User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok |

||

| Line 31: | Line 31: | ||

==Flow diagram and process description== | ==Flow diagram and process description== | ||

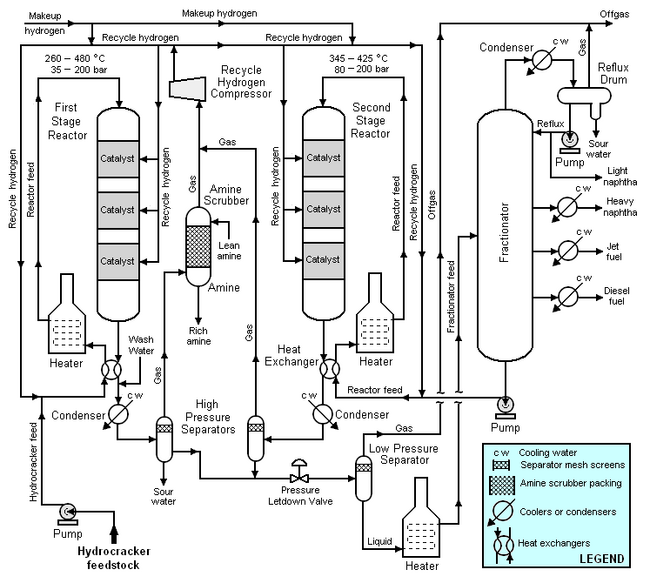

{{Image|Hydrocracking process.png|center| | {{Image|Hydrocracking process.png|center|650px|Schematic flow diagram of a typical hydrocracker.}} | ||

==References== | ==References== | ||

{{reflist}} | {{reflist}} | ||

Revision as of 01:10, 19 July 2009

Hydrocracking is a catalytic process used in petroleum refineries for converting the high-boiling constituent hydrocarbons in petroleum crude oils to more valuable lower-boilng products such as gasoline, kerosene, jet fuel and diesel oil. The process takes place in a hydrogen-rich atmosphere at elevated temperatures (260 – 425 °C) and pressures (35 – 200 bar).[1][2][3]

Basically, the process cracks the high-boiling, high molecular weight hydrocarbons into lower-boiling, lower molecular weight olefinic and aromatic hydrocarbons and then hydrogenates them. Any sulfur and nitrogen present in the hydrocracking feedstock are, to a large extent, also hydrogenated and form gaseous hydrogen sulfide (H2S) and ammonia (NH3) which are subsequently removed. The result is that the hydrocracking products are essentially free of sulfur and nitrogen impurities and are mostly

Hydrocracking plants are capable of processing a wide variety of feedstocks of different characteristics to produce a broad range of products. They can be designed and operated to maximize the production of a gasoline blending component (called hydrocrackate) or to maximize the production of diesel oil.

History

Hydrocracking was first developed in Germany as early as 1915 to provide liquid fuels derived from their domestic coal deposits. The first plant that might be considered as a commercial hydrocracking unit began operation in Leuna, Germany in 1927. Similar efforts to convert coal to liquid fuels took place in the Great Britain, France and other countries.

Between 1925 and 1930, Standard Oil of New Jersey collaborated with I.G. Farbenindustrie of Germany to develop hydrocracking technology capable of converting heavy petroleum oils into fuels. Such processes required pressures of 200 – 300 bar and temperatures of over 375 °C and were very expensive.

In 1939, Imperial Chemical Industries of Great Britain developed a two-stage hydrocracking process. During World War II (1939 – 1945), two-stage hydrocracking processes played an important role in producing aviation gasoline in Germany, Great Britain and the United States.

After World War II, hydrocracking technology became less important. The availability of petroleum crude oil from the Middle East removed the motivation to convert coal into liquid fuels. Newly developed fluid catalytic cracking processes were much more economical than hydrocracking for converting high-boiling petroleum oils to fuels.

In the early 1960s, hydrocracking become economical for a number of reasons:

- The automobile industry began manufacturing higher-performing automobiles that required high-octane gasoline.

- Fluid catalytic cracking expanded rapidly to meet the demand for high-octane gasoline. However, fluid catalytic cracking, in additon to producing gasoline, produces a by-product high-boiling oil called cycle oil that is very difficult to recycle for further cracking. However, hydrocracking can crack that cycle oil.

- The switch from railroad steam engines to diesel engines and the introduction of commercial jet aircraft in the 1950's increased the demand for diesel oil and for jet fuel. The flexibility of hydrocracking to produce either gasoline, jet fuel or diesel oil made it desirable for petroleum refineries to install hydrocrackers.

- Zeolite-based catalysts were developed and commercialized during the period from about 1964 to 1966 and they performed much better than the earlier catalysts. Most importantly, they permitted operation at lower pressures than possible with the earlier catalysts. The higher performance and lower operating pressures made possible by the new catalysts resulted in significantly more economical hydcrackers.

Hydrocracking enjoyed rapid growth in the United States during the late 1960s and the early 1970s. By the mid-1970s, hydrocracking had become a mature process and its growth began to moderate. From then on, hydrocracking growth in the United States proceeded at a slow pace. However, at the same time, hydrocracking enjoyed significant growth in Europe, the Asia-Pacific region and the Middle East.

Flow diagram and process description

References

- ↑ James H. Gary and Glenn E. Handwerk (1984). Petroleum Refining: Technology and Economics, 2nd Edition. Marcel Dekker. ISBN 0-8247-7150-8.

- ↑ Editorial Staff (November 2002). "Refining Processes 2002". Hydrocarbon Processing : pages 115 – 117.

- ↑ Naveen Bhutani, Ajay K. Ray and G.P. Rangaiah (2006). "Modeling, Simulation and Multi-objective Optimization of an Industrial Hydrocracking Unit". Ind. Eng. Res. 45 (4): pages 1354 – 1372.