User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 25: | Line 25: | ||

*The ''quad-sector'' design has four sectors. | *The ''quad-sector'' design has four sectors. | ||

In the tri-sector design, the steam generator's hot flue gas flows through the largest sector (usually spanning about half the cross-section of the casing) and transfers some of its heat into the heat-absorbing material within the element. The cooled flue gas is then | In the tri-sector design, the steam generator's hot flue gas flows through the largest sector (usually spanning about half the cross-section of the casing) and transfers some of its heat into the heat-absorbing material within the element. The cooled flue gas is then routed to further treatment in dust removal and other equipment before being vented from the [[flue gas stack]]. Ambient air is blown through the second, smaller sector by a [[centrifugal fan]] and absorbs heat from the heated material as it rotates through that smaller sector. The heated air then flows into the steam generating furnace as combustion air. The third sector is the smallest one and it heats a portion of the ambient air which is then routed into the coal [[pulverizer]]s and is used to transport the coal-air mixture to coal burners. Thus, the total air heated in the RAPH provides: heated primary combustion air, heated air to remove moisture from the pulverised coal and carrier air for transporting the pulverised coal to the coal burners. Since the flue gas [[pressure]] is lower than the pressure of the air being heated, there is some small leakage (between the sectors) of flue gas into the air. | ||

The bi-sector design is used in thermal power plants burning fuels (such as oil or gas) that do not require pulverizing or removal of moisture and therefore have need for heated air other than for combustion air. | The bi-sector design is used in thermal power plants burning fuels (such as oil or gas) that do not require pulverizing or removal of moisture and therefore have need for heated air other than for combustion air. | ||

| Line 36: | Line 36: | ||

=====Construction features===== | =====Construction features===== | ||

In this design the whole air preheater casing is supported on the boiler supporting structure itself with necessary [[expansion joint]]s in the ducting. | In this design the whole air preheater casing is supported on the boiler supporting structure itself with necessary [[expansion joint]]s in the ducting. | ||

| Line 51: | Line 52: | ||

=====Problems===== | =====Problems===== | ||

The boiler flue gas contains many dust particles (due to high ash content) not contributing towards combustion, such as silica, which cause abrasive wear of the baskets, and may also contain corrosive gases depending on the composition of the fuel. For example, [[India]]n coals generally result in high levels of [[Fly ash|ash]], [[sulfur]] and [[silica]] in the flue gas. The wear of the baskets therefore is generally more than other, cleaner-burning fuels. | The boiler flue gas contains many dust particles (due to high ash content) not contributing towards combustion, such as silica, which cause abrasive wear of the baskets, and may also contain corrosive gases depending on the composition of the fuel. For example, [[India]]n coals generally result in high levels of [[Fly ash|ash]], [[sulfur]] and [[silica]] in the flue gas. The wear of the baskets therefore is generally more than other, cleaner-burning fuels. | ||

Revision as of 09:47, 19 May 2009

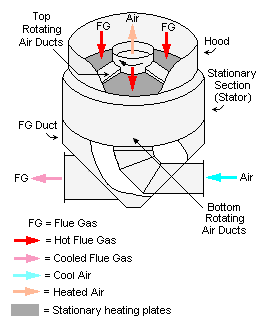

Schematic diagram of a combustion air preheater for the steam generator in a conventional coal-fired power plant.

An air preheater (APH) is a general term to describe any device designed to preheat the combustion air used in a fuel-burning furnace for the purpose of increasing the thermal efficiency of the furnace.

In particular, this article describes the combustion air preheaters for the large fuel-burning furnaces used to generate steam in thermal power plants. The air preheater increases the steam generator's thermal efficiency by preheating the combustion air with heat recovered from the hot combustion flue gases (see the adjacent diagram).

Types

There are two categories of air preheaters for use in steam generators in thermal power plant:one is a regenerative air preheater and the other is a tubular type built into the steam generator's flue gas ducting.[1][2][3][4]

Regenerative air preheaters

The two most commonly used types of regenerator|regenerative air preheaters are

- Rotating-plate regenerative air preheaters (RAPH)

- Stationary-plate regenerative air preheaters (Rothemuhle).

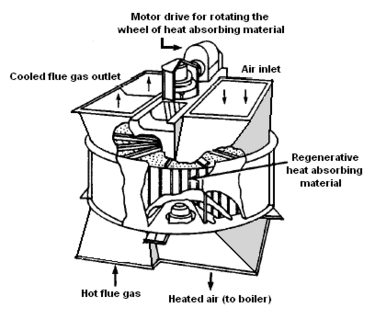

Rotating-plate regenerative air preheater

A typical rotating-plate regenerative air preheater.[2]

The rotating-plate air preheater (RAPH) consists of a central rotating-plate element installed within a casing that is divided into sectors. There are three basic designs for the rotating-plate element:[5][6]

- The bi-sector design has two sectors.

- The tri-sector design has three sectors.

- The quad-sector design has four sectors.

In the tri-sector design, the steam generator's hot flue gas flows through the largest sector (usually spanning about half the cross-section of the casing) and transfers some of its heat into the heat-absorbing material within the element. The cooled flue gas is then routed to further treatment in dust removal and other equipment before being vented from the flue gas stack. Ambient air is blown through the second, smaller sector by a centrifugal fan and absorbs heat from the heated material as it rotates through that smaller sector. The heated air then flows into the steam generating furnace as combustion air. The third sector is the smallest one and it heats a portion of the ambient air which is then routed into the coal pulverizers and is used to transport the coal-air mixture to coal burners. Thus, the total air heated in the RAPH provides: heated primary combustion air, heated air to remove moisture from the pulverised coal and carrier air for transporting the pulverised coal to the coal burners. Since the flue gas pressure is lower than the pressure of the air being heated, there is some small leakage (between the sectors) of flue gas into the air.

The bi-sector design is used in thermal power plants burning fuels (such as oil or gas) that do not require pulverizing or removal of moisture and therefore have need for heated air other than for combustion air.

The quad-sector design has a large sector heated by flue gas and three air-heating sectors: one is for the combustion air and that sector is flanked by two smaller air sectors. In applications such as circulating fluid bed (CFB) combustion systems where the differential between the air pressure and the flue gas pressure is even higher than in a conventional coal-fired steam generator, flue gas pressure, such a design is ideal since it acts to reduce the leakage of air into the flue gas.[7]

The rotating element rotates quite slowly (around 3-5 revolutions per minute) to allow optimum heat transfer first from the hot exhaust gases to the element and then, as it rotates, from the element to the air in the other sectors.

The RAPH was invented by Fredrik Ljungström, who was a Swedish engineer, and is therefore commonly referred to as a Ljungström air preheater.

Construction features

In this design the whole air preheater casing is supported on the boiler supporting structure itself with necessary expansion joints in the ducting.

The vertical rotor is supported on thrust bearings at the lower end and has an oil bath lubrication, cooled by water circulating in coils inside the oil bath. This arrangement is for cooling the lower end of the shaft, as this end of the vertical rotor is on the hot end of the ducting. The top end of the rotor has a simple roller bearing to hold the shaft in a vertical position.

The rotor is built up on the vertical shaft with radial supports and cages for holding the baskets in position. Radial and circumferential seal plates are also provided to avoid leakages of gases or air between the sectors or between the duct and the casing while in rotation.

For on line cleaning of the deposits from the baskets steam jets are provided such that the blown out dust and ash are collected at the bottom ash hopper of the air preheater. This dust hopper is connected for emptying along with the main dust hoppers of the dust collectors.

The rotor is turned by an air driven motor and gearing, and is required to be started before starting the boiler and also to be kept in rotation for some time after the boiler is stopped, to avoid uneven expansion and contraction resulting in warping or cracking of the rotor. The station air is generally totally dry (dry air is required for the instrumentation), so the air used to drive the rotor is injected with oil to lubricate the air motor.

Safety protected inspection windows are provided for viewing the preheater's internal operation under all operating conditions.

The baskets are in the sector housings provided on the rotor and are renewable. The life of the baskets depend on the ash abrasiveness and corrosiveness of the boiler outlet gases.

Problems

The boiler flue gas contains many dust particles (due to high ash content) not contributing towards combustion, such as silica, which cause abrasive wear of the baskets, and may also contain corrosive gases depending on the composition of the fuel. For example, Indian coals generally result in high levels of ash, sulfur and silica in the flue gas. The wear of the baskets therefore is generally more than other, cleaner-burning fuels.

In this RAPH, the dust laden, corrosive boiler gases have to pass between the elements of air preheater baskets. The elements are made up of zig zag corrugated plates pressed into a steel basket giving sufficient annular space in between for the gas to pass through. These plates are corrugated to give more surface area for the heat to be absorbed and also to give it the rigidity for stacking them into the baskets. Hence frequent replacements are called for and new baskets are always kept ready. In the early days, Cor-ten steel was being used for the elements. Today due to technological advance many manufacturers may use their own patents. Some manufacturers supply different materials for the use of the elements to lengthen the life of the baskets.

In certain cases the unburnt deposits may occur on the air preheater elements causing it to catch fire during normal operations of the boiler, giving rise to explosions inside the air preheater. Sometimes mild explosions may be detected in the control room by variations in the inlet and outlet temperatures of the combustion air.

Stationary-plate regenerative air preheater

The heating plate elements in this type of regenerative air preheater are also installed in a casing, but the heating plate elements are stationary rather than rotating. Instead the air ducts in the preheater are rotated so as to alternately expose sections of the heating plate elements to the upflowing cool air.

As indicated in the adjacent drawing, there are rotating inlet air ducts at the bottom of the stationary plates similar to the rotating outlet air ducts at the top of the stationary plates.

Stationary-plate regenerative air preheaters are also known as Rothemuhle preheaters, so-named after the town in Germany where they were manufactured for many years.

Tubular type

Construction features

Tubular preheaters consist of straight tube bundles which pass through the outlet ducting of the boiler and open at each end outside of the ducting. Inside the ducting, the hot furnace gases pass around the preheater tubes, transferring heat from the exhaust gas to the air inside the preheater. Ambient air is forced by a fan through ducting at one end of the preheater tubes and at other end the heated air from inside of the tubes emerges into another set of ducting, which carries it to the boiler furnace for combustion.

Problems

The tubular preheater ductings for cold and hot air require more space and structural supports than a rotating preheater design. Further, due to dust-laden abrasive flue gases, the tubes outside the ducting wear out faster on the side facing the gas current. Many advances have been made to eliminate this problem such as the use of ceramic and hardened steel.

Many new circulating fluidized bed (CFB) and bubbling fluidized bed (BFB) steam generators are currently incorporating tubular air heaters offering an advantage with regards to the moving parts of a rotary type.

Dew point corrosion

Dew point corrosion occurs for a variety of reasons.[8][9] The type of fuel used, its sulfur content and moisture content are contributing factors. However, by far the most significant cause of dew point corrosion is the metal temperature of the tubes. If the metal temperature within the tubes drops below the acid saturation temperature, usually at between 190°F (88°C)and 230°F (110°C), but sometimes at temperatures as high as 260°F (127°C), then the risk of dew point corrosion damage becomes considerable.

References

- ↑ Sadik Kakaç and Hongtan Liu (2002). Heat Exchangers: Selection, Rating and Thermal Design, 2nd Edition. CRC Press. ISBN 0-8493-0902-6.

- ↑ 2.0 2.1 Course SI:428A Online publication of the U.S. Environmental Protection Agency's Air Pollution Training Institute, known as APTI (Scroll down to page 23 of 28)

- ↑ Sadik Kakaç (Editor) (April, 1991). Boilers. Evaporators and Condensers. Wiley Interscience. ISBN 0-471-62170-6. (See Chapter 8 by Z.H. Lin)

- ↑ Lawrence Drbak, Patrica Boston, Kalya Westra, and R. Bruce Erickson (Editors) (1996). Power Plant Engineering (Black and Veatch). Chapman & Hall. ISBN 0-412-06401-4.

- ↑ The Ljungström® Air Preheater

- ↑ Ljungström® Air Preheater Arrangements

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedSectors - ↑ Examples of dewpoint corrosion

- ↑ More examples of dewpoint corrosion

External links

- Overview & Technology of a continuously rotating cylinder air preheater

- Trisector Ljungström Air Preheater

- Reducing Preheater Leakage Boosts Output and Availability from Power Engineering website, May 23. 2007.

Bibliography

- Babcock & Wilcox Co. (2005). Steam: Its Generation and Use, 41st edition. ISBN 0-9634570-0-4.

- British Electricity International (1991). Modern Power Station Practice: incorporating modern power system practice, 3rd Edition (12 volume set). Pergamon. ISBN 0-08-040510-X.