User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok No edit summary |

||

| Line 1: | Line 1: | ||

A '''gas compressor''' is a mechanical device that increases the [[pressure]] of a [[gas]] by reducing its [[volume]]. A gas compressor is similar to a liquid pump in that both increase the pressure of fluid and both can transport the fluid through [[piping]]. | |||

== Types of compressors == | |||

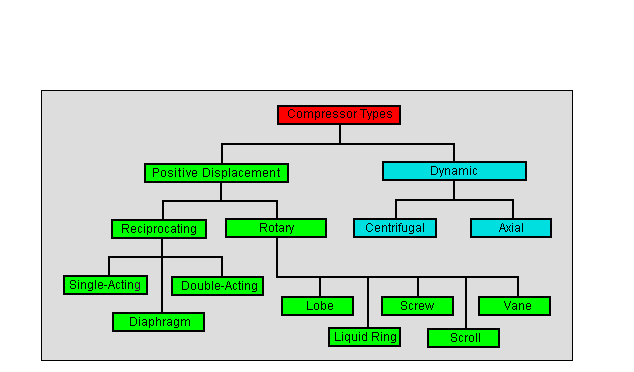

The main types of gas compressors are illustrated and discussed below: | |||

[[Image:Compressor Types.png|frame|center]] | |||

=== Centrifugal compressors === | |||

{{main|Centrifugal compressor}} | |||

[[Image:CentrifugalCompressor.jpg|thumb|right|250px|Figure 1: A single stage centrifugal compressor]] | |||

'''Centrifugal compressors''' use a rotating disk or [[impeller]] in a shaped housing to force the gas to the rim of the impeller, increasing the velocity of the gas. A [[diffuser]] (divergent duct) section converts the velocity energy to pressure energy. They are primarily used for continuous, stationary service in industries such as [[oil refinery|oil refineries]], [[chemical plant|chemical]] and [[petrochemical]] plants and [[natural gas processing]] plants.<ref name=Perry>{{cite book|author=Perry, R.H. and Green, D.W. (Editors)|title=[[Perry's Chemical Engineers' Handbook]]|edition=8th Edition|publisher=McGraw Hill|year=2007|id=ISBN 0-07-142294-3}}</ref><ref>{{cite book|author=Dixon S.L.|title=Fluid Mechanics, Thermodynamics of Turbomachinery|edition=Third Edition|publisher=Pergamon Press|year=1978|id=ISBN 0-08-022722-8}}</ref><ref>{{cite book|author=Aungier, Ronald H.|title=Centrifugal Compressors A Strategy for Aerodynamic design and Analysis|edition=|publisher=[[ASME]] Press|year=2000|id=ISBN 0-7918-0093-8}}</ref> Their application can be from 100 hp (75 kW) to thousands of horsepower. With multiple staging, they can achieve extremely high output pressures greater than 10,000 psi (69 MPa). | |||

Many large snow-making operations (like [[ski resorts]]) use this type of compressor. They are also used in internal combustion engines as superchargers and [[turbocharger]]s. Centrifugal compressors are used in small [[gas turbine]] [[engine]]s or as the final compression stage of medium sized gas turbines. | |||

===Diagonal or mixed-flow compressors=== | |||

{{main|Diagonal or mixed-flow compressor}} | |||

'''Diagonal''' or '''mixed-flow compressors''' are similar to centrifugal compressors, but have a radial and axial velocity component at the exit from the rotor. The diffuser is often used to turn diagonal flow to the axial direction. The diagonal compressor has a lower diameter diffuser than the equivalent centrifugal compressor. | |||

===Axial-flow compressors=== | |||

{{main|Axial-flow compressor}} | |||

[[Image:Axial compressor.gif|thumb|right|250 px|An animation of an axial compressor.]] | |||

'''Axial-flow compressors''' are dynamic rotating compressors that use arrays of fan-like [[aerofoils]] to progressively compress the working fluid. They are used where there is a requirement for a high flows or a compact design. | |||

The arrays of aerofoils are set in rows, usually as pairs: one rotating and one stationary. The rotating aerofoils, also known as blades or ''rotors'', accelerate the fluid. The stationary aerofoils, also known as a ''stators'' or vanes, turn and decelerate the fluid; preparing and redirecting the flow for the rotor blades of the next stage.<ref name=Perry/> Axial compressors are almost always multi-staged, with the cross-sectional area of the gas passage diminishing along the compressor to maintain an optimum axial [[Mach number]]. Beyond about 5 stages or a 4:1 design pressure ratio, [[variable geometry]] is normally used to improve operation. | |||

Axial compressors can have high efficiencies; around 90% [[polytropic]] at their design conditions. However, they are relatively expensive, requiring a large number of components, tight tolerances and high quality materials. Axial-flow compressors can be found in medium to large [[gas turbine]] engines, in natural gas pumping stations, and within certain chemical plants. | |||

===Reciprocating compressors=== | |||

[[Image:ReciprocatingCompressor.jpg|right|thumb|250px|A motor-driven six-cylinder reciprocating compressor that can operate with two, four or six cylinders.]] | |||

{{main|Reciprocating compressor}} | |||

'''Reciprocating compressors''' use [[piston]]s driven by a crankshaft. They can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines.<ref name=Perry/><ref>{{cite book|author=Bloch, H.P. and Hoefner, J.J.|title=Reciprocating Compressors, Operation and Maintenance|edition=|publisher=Gulf Professional Publishing|year=1996|id=ISBN 0-88415-525-0 | |||

}}</ref> | |||

<ref>[http://www.machinerylubrication.com/article_detail.asp?articleid=775&pagetitle=Reciprocating%20Compressor%20Basics Reciprocating Compressor Basics] Adam Davis, Noria Corporation, ''Machinery Lubrication'', July 2005</ref> Small reciprocating compressors from 5 to 30 [[horsepower]] (hp) are commonly seen in automotive applications and are typically for intermittent duty. Larger reciprocating compressors well over 1000 hp are still commonly found in large industrial and petroleum applications. Discharge pressures can range from low pressure to very high pressure (>5000 psi or 35 MPa). In certain applications, such as air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, noisier, and more costly than comparable rotary units.<ref>[http://www.compressedairchallenge.org/content/library/sourcebook/html/intro_ca.htm Introduction to Industrial Compressed Air Systems]</ref> | |||

===Rotary screw compressors=== | |||

[[Image:RotaryScrewCompressor.gif|thumb|right|360px|Diagram of a rotary screw compressor]] | |||

{{main|Rotary screw compressor}} | |||

'''Rotary screw compressors''' use two meshed rotating positive-displacement [[Helix|helical screws]] to force the gas into a smaller space.<ref name=Perry/><ref>[http://www.blackmer.com/tech-screw.jsp Screw Compressor] Describes how screw compressors work and include photographs.</ref><ref>[http://www.domnickhunter.com/tech_Centre.asp?chapter=1§ion=3_Screw-Compressors_2_3.htm&getIndex=false Technical Centre] Discusses oil-flooded screw compressors including a complete system flow diagram</ref> These are usually used for continuous operation in commercial and industrial applications and may be either stationary or portable. Their application can be from 3 hp (2.24 kW) to over 500 hp (375 kW) and from low pressure to very high pressure (>1200 psi or 8.3 MPa). | |||

===Rotary vane compressors=== | |||

{{See also|Rotary vane pump}} | |||

'''Rotary vane compressors''' consist of a rotor with a number of blades inserted in radial slots in the rotor. The rotor is mounted offset in a larger housing which can be circular or a more complex shape. As the rotor turns, blades slide in and out of the slots keeping contact with the outer wall of the housing.<ref name=Perry/> Thus, a series of decreasing volumes is created by the rotating blades. Rotary Vane compressors are, with piston compressors one of the oldest of compressor technologies. | |||

With suitable port connections, the devices may be either a compressor or a vacuum pump. They can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines. Dry vane machines are used at relatively low pressures (e.g., 2 bar) for bulk material movement whilst oil-injected machines have the necessary volumetric efficiency to achieve pressures up to about 13 bar in a single stage. A rotary vane compressor is well suited to electric motor drive and is significantly quieter in operation than the equivalent piston compressor. | |||

===Scroll compressors=== | |||

{{main|Scroll compressor}} | |||

[[Image:Two moving spirals scroll pump.gif|thumb|right|Mechanism of a scroll pump]] | |||

A '''scroll compressor''', also known as '''scroll pump''' and '''scroll vacuum pump''', uses two interleaved spiral-like vanes to [[pump]] or [[Gas compressor|compress]] [[fluid]]s such as [[liquids]] and [[gas]]es. The vane geometry may be [[involute]], [[archimedean spiral]], or hybrid curves.<ref>Tischer, J., Utter, R: “Scroll Machine Using Discharge Pressure For Axial Sealing,” U.S. Patent 4522575, 1985.</ref><ref>Caillat, J., Weatherston, R., Bush, J: “Scroll-Type Machine With Axially Compliant Mounting,” U.S. Patent 4767293, 1988.</ref><ref>Richardson, Jr., Hubert: “Scroll Compressor With Orbiting Scroll Member Biased By Oil Pressure,” U.S. Patent 4875838, 1989.</ref> They operate more smoothly, quietly, and reliably than other types of compressors in the lower volume range | |||

Often, one of the scrolls is fixed, while the other orbits eccentrically without rotating, thereby trapping and pumping or compressing pockets of fluid or gas between the scrolls. | |||

===Diaphragm compressors=== | |||

{{main|Diaphragm compressor}} | |||

A '''diaphragm compressor''' (also known as a '''membrane compressor''') is a variant of the conventional reciprocating compressor. The compression of gas occurs by the movement of a flexible membrane, instead of an intake element. The back and forth movement of the membrane is driven by a rod and a crankshaft mechanism. Only the membrane and the compressor box come in touch with the gas being compressed.<ref name=Perry/> | |||

Diaphragm compressors are used for hydrogen and compressed natural gas ([[Compressed natural gas|CNG]]) as well as in a number of other applications. | |||

[[Image:DiaphragmCompressor.jpg|thumb|right|275px|A three-stage diaphragm compressor]] | |||

The photograph included in this section depicts a three-stage diaphragm compressor used to compress [[hydrogen]] gas to 6,000 psi (41 MPa) for use in a prototype [[compressed hydrogen]] and [[compressed natural gas]] (CNG) fueling station built in downtown [[Phoenix, Arizona]] by the [[Arizona Public Service]] company (an electric utilities company). [[Reciprocating compressor]]s were used to compress the [[natural gas]]. | |||

The prototype [[alternative fuel]]ing station was built in compliance with all of the prevailing safety, environmental and building codes in Phoenix to demonstrate that such fueling stations could be built in urban areas. | |||

== Compressor drivers== | |||

There are many types of equipment, often referred to as ''prime movers'', which can be used to drive a compressor: | |||

* [[Gas turbine]]s | |||

* [[Steam turbine]]s | |||

* [[Electric motor]]s | |||

* [[Diesel engine]]s or [[gasoline engine]]s | |||

== Applications == | |||

Gas compressors are used in various applications where either higher pressures or lower volumes of gas are needed: | |||

* in [[pipeline transport]] of purified natural gas to move the gas from the production site to the consumer. | |||

* in petroleum refineries, natural gas processing plants, petrochemical and chemical plants, and similar large industrial plants for compressing intermediate and end product gases. | |||

* in [[refrigeration]] and [[air conditioner]] equipment to move [[heat]] from one place to another in [[refrigerant]] cycles: see [[Vapor-compression refrigeration]]. | |||

* in gas turbine systems to compress the intake [[combustion]] air | |||

* in storing purified or manufactured gases in a small volume, high pressure cylinders for [[medical]], [[welding]] and other uses. | |||

* in many various industrial, manufacturing and building processes to power all types of [[pneumatic tools]]. | |||

* as a medium for transferring [[energy]], such as to power [[pneumatic]] equipment. | |||

* in [[Cabin pressurization|pressurised]] aircraft to provide a breathable atmosphere of higher than ambient pressure. | |||

* in some types of [[jet engine]]s (such as [[turbojet]]s and [[turbofan]]s) to provide the air required for combustion of the engine fuel. The power to drive the combustion air compressor comes from the jet's own [[turbine]]s. | |||

* in [[SCUBA diving]], [[hyperbaric oxygen therapy]] and other life support devices to store [[breathing gas]] in a small volume such as in [[diving cylinder]]s. | |||

* in [[submarine]]s, to store air for later use in displacing water from buoyancy chambers, for adjustment of depth. | |||

* in [[turbocharger]]s and [[supercharger]]s to increase the performance of [[internal combustion engine]]s by increasing mass flow. | |||

* in [[Rail transport|rail]] and heavy [[road transport]] to provide [[compressed air]] for operation of [[Air brake (rail)|rail vehicle brakes]] or [[Air brake (road vehicle)|road vehicle brakes]] and various other systems ([[door]]s, [[windscreen wiper]]s, [[engine]]/[[gearbox]] [[control]], etc). | |||

* in miscellaneous uses such as providing compressed air for filling pneumatic [[tire]]s. | |||

==References== | |||

<references/> | |||

== See also == | |||

* [[Vapor-compression refrigeration]] | |||

Revision as of 18:08, 7 September 2008

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. A gas compressor is similar to a liquid pump in that both increase the pressure of fluid and both can transport the fluid through piping.

Types of compressors

The main types of gas compressors are illustrated and discussed below:

Centrifugal compressors

Centrifugal compressors use a rotating disk or impeller in a shaped housing to force the gas to the rim of the impeller, increasing the velocity of the gas. A diffuser (divergent duct) section converts the velocity energy to pressure energy. They are primarily used for continuous, stationary service in industries such as oil refineries, chemical and petrochemical plants and natural gas processing plants.[1][2][3] Their application can be from 100 hp (75 kW) to thousands of horsepower. With multiple staging, they can achieve extremely high output pressures greater than 10,000 psi (69 MPa).

Many large snow-making operations (like ski resorts) use this type of compressor. They are also used in internal combustion engines as superchargers and turbochargers. Centrifugal compressors are used in small gas turbine engines or as the final compression stage of medium sized gas turbines.

Diagonal or mixed-flow compressors

Diagonal or mixed-flow compressors are similar to centrifugal compressors, but have a radial and axial velocity component at the exit from the rotor. The diffuser is often used to turn diagonal flow to the axial direction. The diagonal compressor has a lower diameter diffuser than the equivalent centrifugal compressor.

Axial-flow compressors

Axial-flow compressors are dynamic rotating compressors that use arrays of fan-like aerofoils to progressively compress the working fluid. They are used where there is a requirement for a high flows or a compact design.

The arrays of aerofoils are set in rows, usually as pairs: one rotating and one stationary. The rotating aerofoils, also known as blades or rotors, accelerate the fluid. The stationary aerofoils, also known as a stators or vanes, turn and decelerate the fluid; preparing and redirecting the flow for the rotor blades of the next stage.[1] Axial compressors are almost always multi-staged, with the cross-sectional area of the gas passage diminishing along the compressor to maintain an optimum axial Mach number. Beyond about 5 stages or a 4:1 design pressure ratio, variable geometry is normally used to improve operation.

Axial compressors can have high efficiencies; around 90% polytropic at their design conditions. However, they are relatively expensive, requiring a large number of components, tight tolerances and high quality materials. Axial-flow compressors can be found in medium to large gas turbine engines, in natural gas pumping stations, and within certain chemical plants.

Reciprocating compressors

Reciprocating compressors use pistons driven by a crankshaft. They can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines.[1][4]

[5] Small reciprocating compressors from 5 to 30 horsepower (hp) are commonly seen in automotive applications and are typically for intermittent duty. Larger reciprocating compressors well over 1000 hp are still commonly found in large industrial and petroleum applications. Discharge pressures can range from low pressure to very high pressure (>5000 psi or 35 MPa). In certain applications, such as air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, noisier, and more costly than comparable rotary units.[6]

Rotary screw compressors

Rotary screw compressors use two meshed rotating positive-displacement helical screws to force the gas into a smaller space.[1][7][8] These are usually used for continuous operation in commercial and industrial applications and may be either stationary or portable. Their application can be from 3 hp (2.24 kW) to over 500 hp (375 kW) and from low pressure to very high pressure (>1200 psi or 8.3 MPa).

Rotary vane compressors

- See also: Rotary vane pump

Rotary vane compressors consist of a rotor with a number of blades inserted in radial slots in the rotor. The rotor is mounted offset in a larger housing which can be circular or a more complex shape. As the rotor turns, blades slide in and out of the slots keeping contact with the outer wall of the housing.[1] Thus, a series of decreasing volumes is created by the rotating blades. Rotary Vane compressors are, with piston compressors one of the oldest of compressor technologies.

With suitable port connections, the devices may be either a compressor or a vacuum pump. They can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines. Dry vane machines are used at relatively low pressures (e.g., 2 bar) for bulk material movement whilst oil-injected machines have the necessary volumetric efficiency to achieve pressures up to about 13 bar in a single stage. A rotary vane compressor is well suited to electric motor drive and is significantly quieter in operation than the equivalent piston compressor.

Scroll compressors

A scroll compressor, also known as scroll pump and scroll vacuum pump, uses two interleaved spiral-like vanes to pump or compress fluids such as liquids and gases. The vane geometry may be involute, archimedean spiral, or hybrid curves.[9][10][11] They operate more smoothly, quietly, and reliably than other types of compressors in the lower volume range

Often, one of the scrolls is fixed, while the other orbits eccentrically without rotating, thereby trapping and pumping or compressing pockets of fluid or gas between the scrolls.

Diaphragm compressors

A diaphragm compressor (also known as a membrane compressor) is a variant of the conventional reciprocating compressor. The compression of gas occurs by the movement of a flexible membrane, instead of an intake element. The back and forth movement of the membrane is driven by a rod and a crankshaft mechanism. Only the membrane and the compressor box come in touch with the gas being compressed.[1]

Diaphragm compressors are used for hydrogen and compressed natural gas (CNG) as well as in a number of other applications.

The photograph included in this section depicts a three-stage diaphragm compressor used to compress hydrogen gas to 6,000 psi (41 MPa) for use in a prototype compressed hydrogen and compressed natural gas (CNG) fueling station built in downtown Phoenix, Arizona by the Arizona Public Service company (an electric utilities company). Reciprocating compressors were used to compress the natural gas.

The prototype alternative fueling station was built in compliance with all of the prevailing safety, environmental and building codes in Phoenix to demonstrate that such fueling stations could be built in urban areas.

Compressor drivers

There are many types of equipment, often referred to as prime movers, which can be used to drive a compressor:

Applications

Gas compressors are used in various applications where either higher pressures or lower volumes of gas are needed:

- in pipeline transport of purified natural gas to move the gas from the production site to the consumer.

- in petroleum refineries, natural gas processing plants, petrochemical and chemical plants, and similar large industrial plants for compressing intermediate and end product gases.

- in refrigeration and air conditioner equipment to move heat from one place to another in refrigerant cycles: see Vapor-compression refrigeration.

- in gas turbine systems to compress the intake combustion air

- in storing purified or manufactured gases in a small volume, high pressure cylinders for medical, welding and other uses.

- in many various industrial, manufacturing and building processes to power all types of pneumatic tools.

- as a medium for transferring energy, such as to power pneumatic equipment.

- in pressurised aircraft to provide a breathable atmosphere of higher than ambient pressure.

- in some types of jet engines (such as turbojets and turbofans) to provide the air required for combustion of the engine fuel. The power to drive the combustion air compressor comes from the jet's own turbines.

- in SCUBA diving, hyperbaric oxygen therapy and other life support devices to store breathing gas in a small volume such as in diving cylinders.

- in submarines, to store air for later use in displacing water from buoyancy chambers, for adjustment of depth.

- in turbochargers and superchargers to increase the performance of internal combustion engines by increasing mass flow.

- in rail and heavy road transport to provide compressed air for operation of rail vehicle brakes or road vehicle brakes and various other systems (doors, windscreen wipers, engine/gearbox control, etc).

- in miscellaneous uses such as providing compressed air for filling pneumatic tires.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Perry, R.H. and Green, D.W. (Editors) (2007). Perry's Chemical Engineers' Handbook, 8th Edition. McGraw Hill. ISBN 0-07-142294-3.

- ↑ Dixon S.L. (1978). Fluid Mechanics, Thermodynamics of Turbomachinery, Third Edition. Pergamon Press. ISBN 0-08-022722-8.

- ↑ Aungier, Ronald H. (2000). Centrifugal Compressors A Strategy for Aerodynamic design and Analysis. ASME Press. ISBN 0-7918-0093-8.

- ↑ Bloch, H.P. and Hoefner, J.J. (1996). Reciprocating Compressors, Operation and Maintenance. Gulf Professional Publishing. ISBN 0-88415-525-0.

- ↑ Reciprocating Compressor Basics Adam Davis, Noria Corporation, Machinery Lubrication, July 2005

- ↑ Introduction to Industrial Compressed Air Systems

- ↑ Screw Compressor Describes how screw compressors work and include photographs.

- ↑ Technical Centre Discusses oil-flooded screw compressors including a complete system flow diagram

- ↑ Tischer, J., Utter, R: “Scroll Machine Using Discharge Pressure For Axial Sealing,” U.S. Patent 4522575, 1985.

- ↑ Caillat, J., Weatherston, R., Bush, J: “Scroll-Type Machine With Axially Compliant Mounting,” U.S. Patent 4767293, 1988.

- ↑ Richardson, Jr., Hubert: “Scroll Compressor With Orbiting Scroll Member Biased By Oil Pressure,” U.S. Patent 4875838, 1989.