User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 14: | Line 14: | ||

[[Image:Demethanizer.PNG|right|thumb|350px|{{#ifexist:Template:Demethanizer.PNG/credit|{{Demethanizer.PNG/credit}}<br/>|}}Fig. 2: A schematic diagram of a demethanizer extracting hydrocarbon liquids from natural gas.]] | [[Image:Demethanizer.PNG|right|thumb|350px|{{#ifexist:Template:Demethanizer.PNG/credit|{{Demethanizer.PNG/credit}}<br/>|}}Fig. 2: A schematic diagram of a demethanizer extracting hydrocarbon liquids from natural gas.]] | ||

Raw natural gas consists primarily of methane (CH<sub>4</sub>), the shortest and lightest [[hydrocarbon]] molecule, as well as various amounts of heavier hydrocarbon gases such as [[ethane]] (C<sub>2</sub>H<sub>6</sub>), [[propane]] (C<sub>3</sub>H<sub>8</sub>), [[Butane|normal butane]] (n-C<sub>4</sub>H<sub>10</sub>), [[isobutane]] (i-C<sub>4</sub>H<sub>10</sub>), [[pentane]]s and even higher [[molecular weight]] hydrocarbons. The raw gas also contains various amounts of [[acid gas]]es such as [[carbon dioxide]] (CO<sub>2</sub>), [[hydrogen sulfide]] (H<sub>2</sub>S) and [[mercaptan]]s such as [[methanethiol]] (CH<sub>3</sub>SH) and [[ethanethiol]] | Raw natural gas consists primarily of methane (CH<sub>4</sub>), the shortest and lightest [[hydrocarbon]] molecule, as well as various amounts of heavier hydrocarbon gases such as [[ethane]] (C<sub>2</sub>H<sub>6</sub>), [[propane]] (C<sub>3</sub>H<sub>8</sub>), [[Butane|normal butane]] (n-C<sub>4</sub>H<sub>10</sub>), [[isobutane]] (i-C<sub>4</sub>H<sub>10</sub>), [[pentane]]s and even higher [[molecular weight]] hydrocarbons. The raw gas also contains various amounts of [[acid gas]]es such as [[carbon dioxide]] (CO<sub>2</sub>), [[hydrogen sulfide]] (H<sub>2</sub>S) and [[mercaptan]]s such as [[methanethiol]] (CH<sub>3</sub>SH) and [[ethanethiol]] (C<sub>2</sub>H<sub>5</sub>SH). | ||

When processed into finished by-products (see [[Natural gas processing]]), these heavier hydrocarbons are collectively referred to as NGL (natural gas liquids). The extraction of the NGL often involves an expansion turbine and a low-temperature distillation column (called a ''demethanizer'') as shown in Figure 1. The inlet gas to the demethanizer is first cooled to about −51 °C in a [[heat exchanger]] (referred to as a ''cold box'') which partially vaporizes the inlet gas. The resultant gas-liquid mixture is then separated into a gas stream and a liquid stream. | |||

The liquid stream from the [[gas-liquid separator]] flows through a valve and undergoes a [[Flash_evaporation#Flash_evaporation of a single-component liquid|''throttling expansion'']], which is an [[enthalpic]] process (i.e., a constant enthalpy process) that results in lowering the temperature of the stream to about −81 °C as the stream enters the demethanizer. | |||

Revision as of 16:11, 10 July 2008

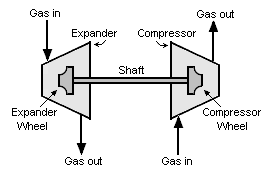

An expansion turbine, also referred to as a turboexpander or turbo-expander, is a centrifugal or axial flow turbine through which a high pressure gas is expanded to produce work that is often used to drive a gas compressor.

Because work is extracted from the expanding high pressure gas, the expansion is an isentropic process (i.e., a constant entropy process) and the low pressure exhaust gas from the turbine is at a very low temperature, sometimes as low as -90 °C or less.

Expansion turbines are very widely used as sources of refrigeration in industrial processes such as the extraction of ethane and natural gas liquids (NGLs) from natural gas,[1] the liquefaction of gases (such as oxygen, nitrogen, helium, argon and krypton)[2][3] and other low-temperature processes.

Applications

Although expansion turbines are very commonly used in low-temperature processes, they are used in many other applications as well. This section discusses one of the low temperature procesees as well as some of the other applications.

Extracting hydrocarbon liquids from natural gas

Raw natural gas consists primarily of methane (CH4), the shortest and lightest hydrocarbon molecule, as well as various amounts of heavier hydrocarbon gases such as ethane (C2H6), propane (C3H8), normal butane (n-C4H10), isobutane (i-C4H10), pentanes and even higher molecular weight hydrocarbons. The raw gas also contains various amounts of acid gases such as carbon dioxide (CO2), hydrogen sulfide (H2S) and mercaptans such as methanethiol (CH3SH) and ethanethiol (C2H5SH).

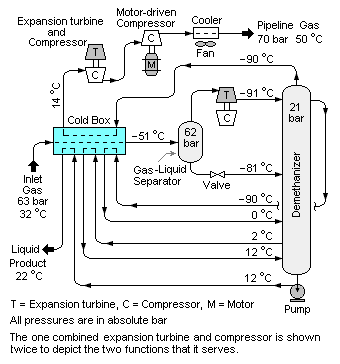

When processed into finished by-products (see Natural gas processing), these heavier hydrocarbons are collectively referred to as NGL (natural gas liquids). The extraction of the NGL often involves an expansion turbine and a low-temperature distillation column (called a demethanizer) as shown in Figure 1. The inlet gas to the demethanizer is first cooled to about −51 °C in a heat exchanger (referred to as a cold box) which partially vaporizes the inlet gas. The resultant gas-liquid mixture is then separated into a gas stream and a liquid stream.

The liquid stream from the gas-liquid separator flows through a valve and undergoes a throttling expansion, which is an enthalpic process (i.e., a constant enthalpy process) that results in lowering the temperature of the stream to about −81 °C as the stream enters the demethanizer.

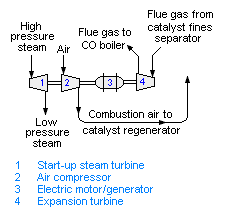

Power recovery in fluid catalytic cracker

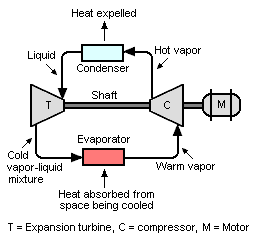

Refrigeration system

Power generation

History

In 1939, Pyotr Kapitza of Russia suggested the use of a centrifugal turbine for the isentropic expansion of gases to produce refrigeration. Since then, centrifugal expansion turbines have taken over almost 100 percent of the gas liquefaction and other low-temperature industrial requirements.

References

- ↑ Demethanzer

- ↑ BOC (NZ) publication: use search function for keyword "expansion"

- ↑ US Department of Energy Hydrogen Program