User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok No edit summary |

||

| Line 3: | Line 3: | ||

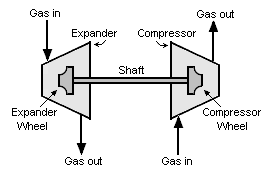

An '''expansion turbine''', also referred to as a '''turboexpander''' or '''turbo-expander''', is a centrifugal or axial flow [[turbine]] through which a high [[pressure]] [[gas]] is expanded to produce work that is often used to drive a [[gas compressor]]. | An '''expansion turbine''', also referred to as a '''turboexpander''' or '''turbo-expander''', is a centrifugal or axial flow [[turbine]] through which a high [[pressure]] [[gas]] is expanded to produce work that is often used to drive a [[gas compressor]]. | ||

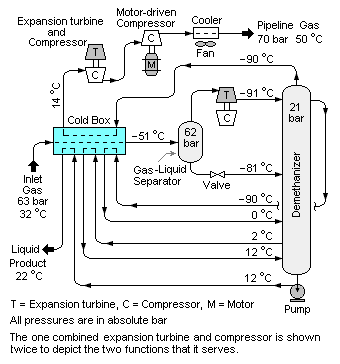

Because work is extracted from the expanding high pressure gas, the expansion is an [[isentropic]] process (i.e., a constant [[entropy]] process) and the low pressure exhaust gas from the turbine is at a very low [[temperature]], as low as | Because work is extracted from the expanding high pressure gas, the expansion is an [[isentropic]] process (i.e., a constant [[entropy]] process) and the low pressure exhaust gas from the turbine is at a very low [[temperature]], sometimes as low as -90 °C or less. Expansion turbines are very widely used as sources of [[refrigeration]] in industrial processes such as the extraction of [[ethane]] and [[Natural gas processing|natural gas liquids]] (NGLs) from [[natural gas]],<ref>[http://freepatentsonline.com/US6915662.html Demethanzer]</ref> the liquefaction of [[gases]] (such as [[oxygen]], [[nitrogen]], [[helium]], [[argon]] and [[krypton]])<ref>[http://www.nzic.org.nz/ChemProcesses/production/1K.pdf BOC (NZ) publication]: use search function for keyword "expansion"</ref><ref>[http://www.hydrogen.energy.gov/pdfs/progress05/v_e_1_shimko.pdf US Department of Energy Hydrogen Program]</ref> and other low-temperature processes. | ||

==Applications== | ==Applications== | ||

| Line 38: | Line 36: | ||

==History== | ==History== | ||

In 1939, [[Pyotr Kapitza]] of [[Russia]] suggested the use of a centrifugal turbine for the isentropic expansion of gases to produce refrigeration. Since then, centrifugal expansion turbines have taken over almost 100 percent of the gas liquefaction and other low-temperature industrial requirements. | |||

==References== | ==References== | ||

{{reflist}} | {{reflist}} | ||

Revision as of 01:35, 10 July 2008

An expansion turbine, also referred to as a turboexpander or turbo-expander, is a centrifugal or axial flow turbine through which a high pressure gas is expanded to produce work that is often used to drive a gas compressor.

Because work is extracted from the expanding high pressure gas, the expansion is an isentropic process (i.e., a constant entropy process) and the low pressure exhaust gas from the turbine is at a very low temperature, sometimes as low as -90 °C or less. Expansion turbines are very widely used as sources of refrigeration in industrial processes such as the extraction of ethane and natural gas liquids (NGLs) from natural gas,[1] the liquefaction of gases (such as oxygen, nitrogen, helium, argon and krypton)[2][3] and other low-temperature processes.

Applications

Extracting hydrocarbon liquids from natural gas

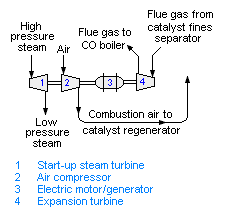

Power recovery in fluid catalytic cracker

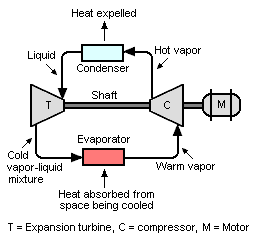

Refrigeration system

Power generation

History

In 1939, Pyotr Kapitza of Russia suggested the use of a centrifugal turbine for the isentropic expansion of gases to produce refrigeration. Since then, centrifugal expansion turbines have taken over almost 100 percent of the gas liquefaction and other low-temperature industrial requirements.

References

- ↑ Demethanzer

- ↑ BOC (NZ) publication: use search function for keyword "expansion"

- ↑ US Department of Energy Hydrogen Program