User:Milton Beychok/Sandbox: Difference between revisions

Jump to navigation

Jump to search

imported>Milton Beychok No edit summary |

imported>Milton Beychok No edit summary |

||

| Line 7: | Line 7: | ||

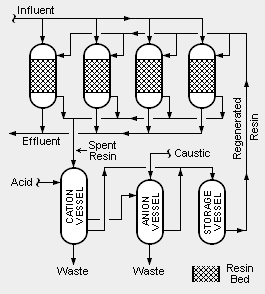

{{Image|Condensate Polisher.png|right|265px|Schematic diagram of a mixed-bed condensate polisher.}} | {{Image|Condensate Polisher.png|right|265px|Schematic diagram of a mixed-bed condensate polisher.}} | ||

==How | ==How ion exchange resins work== | ||

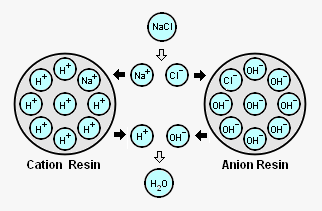

{{Image|Ion Exchange.PNG|right|322px|Diagram depicting how ion exchange resins work.}} | {{Image|Ion Exchange.PNG|right|322px|Diagram depicting how ion exchange resins work.}} | ||

Revision as of 18:27, 5 August 2009

Condensate polishing is a process used to purify the steam condensate produced in high-pressure steam generation facilities[1][2][3][4] such as those in large thermal power plants.[5] Steam condensate is the water formed by condensing the exhaust steam from the steam-driven turbines in thermal power plants and which is recycled for reuse as the major part of the steam generation feedwater.

Condensate polishing is a unique application of ion-exchange resins that removes suspended and dissolved impurities from the condensate. It is essential for the very stringent quality required of high-pressure steam generation feedwater.

Types of condensate polishing

How ion exchange resins work

References

- ↑ Larry Drbal, Kayla Westra and Pat Boston (1996). Power Plant Engineering, 1st Edition. Springer. ISBN 0-412-06401-4.

- ↑ Brad Buecker (2000). Fundamentals of Steam Generation Chemistry, 1st Edition. Penwell. ISBN 0-87814-750-0.

- ↑ Condensate Polishing Guidelines Electric Power Research Institute (EPRI), 1996

- ↑ Condensate Polishing State of Knowledge Assessment Electric Power Research Institute (EPRI), 2006

- ↑ Either nuclear or fuel-fired power plants