User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 79: | Line 79: | ||

==Centrifugal fan performance ratings== | ==Centrifugal fan performance ratings== | ||

A centrifugal fan is a constant volume device, meaning that it will move the same volume of air at two different temperatures. In the United States, tabulated fan performance ratings of discharge static pressure (SP) in inches of water (in H<sub>2</sub>O or " H<sub>2</sub>O) versus volumetric capacity in standard CFM ([[U.S. customary units|cubic feet]] per minute) and required driver power (BHP) are available from fan manufacturers. Fan manufacturers define a standard [[U.S. customary units|cubic foot]] (0.0283 cubic metres) of air as clean, dry air at an absolute pressure of 14.696 [[U.S. customary units|psi]] (101.325 kPa} and a temperature of 70 °F (21 °C), which amounts to air at a standard [[Density (chemistry)|density]] of 0.075 [[U.S. customary units|lb]]/[[U.S. customary units|ft]]³ (1.20 kg/m³). Thus, fan performance tables are based on moving standard air at 70 °F and at an absolute pressure of 14.696 psi, and having a density of 0.075 lb/ft³.<ref name=NYB>[http://www.mpair.com/library.active/nyb.engineering.letters/engltr4.pdf NYB Engineering Letter]</ref> | A centrifugal fan is a constant volume device, meaning that it will move the same volume of air at two different temperatures. In the United States, tabulated fan performance ratings of discharge static pressure (SP) in inches of water (in H<sub>2</sub>O or " H<sub>2</sub>O) versus volumetric capacity in standard CFM ([[U.S. customary units|cubic feet]] per minute) and required driver power (BHP) are available from fan manufacturers. | ||

Fan manufacturers define a standard [[U.S. customary units|cubic foot]] (0.0283 cubic metres) of air as clean, dry air at an absolute pressure of 14.696 [[U.S. customary units|psi]] (101.325 kPa} and a temperature of 70 °F (21 °C), which amounts to air at a standard [[Density (chemistry)|density]] of 0.075 [[U.S. customary units|lb]]/[[U.S. customary units|ft]]³ (1.20 kg/m³). Thus, fan performance tables are based on moving standard air at 70 °F and at an absolute pressure of 14.696 psi, and having a density of 0.075 lb/ft³.<ref name=NYB>[http://www.mpair.com/library.active/nyb.engineering.letters/engltr4.pdf NYB Engineering Letter]</ref> | |||

Again, a centrifugal fan is a constant volume device that will move the same amount of air at two different temperatures. Thus, a centrifugal fan that moves 1,000 ft³/min (28 m³/min) at 70 °F (21 °C) will also move 1,000 ft³/min at 200 °F (93 °C). However, since a given volume of 200 °F air weighs much less than the same volume of 70 °F air, the fan will create a lower discharge pressure and will require less driver power. | Again, a centrifugal fan is a constant volume device that will move the same amount of air at two different temperatures. Thus, a centrifugal fan that moves 1,000 ft³/min (28 m³/min) at 70 °F (21 °C) will also move 1,000 ft³/min at 200 °F (93 °C). However, since a given volume of 200 °F air weighs much less than the same volume of 70 °F air, the fan will create a lower discharge pressure and will require less driver power. | ||

Revision as of 18:16, 21 October 2008

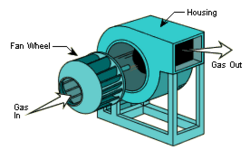

A centrifugal fan (also squirrel-cage fan, as it looks like a hamster wheel) is a mechanical device for moving air or other gases. It has a fan wheel composed of a number of fan blades, or ribs, mounted around a hub. As shown in Figure 1, the hub turns on a driveshaft that passes through the fan housing. The gas enters from the side of the fan wheel, turns 90 degrees and accelerates due to centrifugal force as it flows over the fan blades and exits the fan housing.[1]

Centrifugal fans can generate pressure rises in the gas stream. Accordingly, they are well-suited for industrial processes and air pollution control systems. They are also common in central heating/cooling systems.

Fan components

The major components of a typical centrifugal fan include the fan wheel, fan housing, drive mechanism, and inlet and/or outlet dampers.

Types of drive mechanisms

The fan drive determines the speed of the fan wheel (impeller) and the extent to which this speed can be varied. There are three basic types of fan drives.[1]

Direct drive

The fan wheel can be linked directly to the shaft of an electric motor. This means that the fan wheel speed is identical to the motor's rotational speed. With this type of fan drive mechanism, the fan speed cannot be varied unless the motor speed is adjustable.

Belt drive

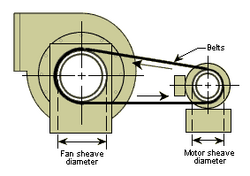

Belt driven fans use multiple belts that rotate in a set of sheaves mounted on the motor shaft and the fan wheel shaft.

This type of drive mechanism is depicted in figure 2. The belts transmit the mechanical energy from the motor to the fan.

The fan wheel speed depends upon the ratio of the diameter of the motor sheave to the diameter of the fan wheel sheave and can be obtained from this equation:[1]

| where: | |

| = fan wheel speed, revolutions per minute | |

| = motor nameplate speed, revolutions per minute | |

| = diameter of the motor sheave | |

| = diameter of the fan wheel sheave |

Fan wheel speeds in belt-driven fans are fixed unless the belts slip. Belt slippage can reduce the fan wheel speed several hundred revolutions per minute (rpm).

Variable drive

Variable drive fans use hydraulic or magnetic couplings (between the fan wheel shaft and the motor shaft) that allow control of the fan wheel speed independent of the motor speed. The fan speed controls are often integrated into automated systems to maintain the desired fan wheel speed.[1]

An alternate method of varying the fan speed is by use of an electronic variable-speed drive which controls the speed of the motor driving the fan. This offers better overall energy efficiency at reduced speeds than mechanical couplings.

Fan dampers

Fan dampers are used to control gas flow into and out of the centrifugal fan. They may be installed on the inlet side or on the outlet side of the fan, or both. Dampers on the outlet side impose a flow resistance that is used to control gas flow. Dampers on the inlet side are designed to control gas flow and to change how the gas enters the fan wheel.

Inlet dampers reduce fan energy usage due to their ability to affect the airflow pattern into the fan.[1]

Fan blades

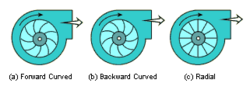

The fan wheel consists of a hub on which a number of fan blades are attached. The fan blades on the hub can be arranged in three different ways: forward-curved, backward-curved or radial.[1]

Forward-curved blades

Forward-curved blades, as in Figure 3(a), use blades that curve in the direction of the fan wheel's rotation. These are especially sensitive to particulates. Forward-curved blades are for high flow, low pressure applications.

Backward-curved blades

Backward-curved blades, as in Figure 3(b), use blades that curve against the direction of the fan wheel's rotation. These types of fan wheels are used in fans designed to handle gas streams with relatively low particulate loadings because they are prone to solids build-up. Backward-curved fans are more energy efficient than radial blade fans. Backward curved blades are used for high pressure, low flow applications.

Straight radial blades

Radial fan blades, as in Figure 3(c), extend straight out from the hub. A radial blade fan wheel is often used on particulate-laden gas streams because it is the least sensitive to solids build-up on the blades.

Centrifugal fan performance ratings

A centrifugal fan is a constant volume device, meaning that it will move the same volume of air at two different temperatures. In the United States, tabulated fan performance ratings of discharge static pressure (SP) in inches of water (in H2O or " H2O) versus volumetric capacity in standard CFM (cubic feet per minute) and required driver power (BHP) are available from fan manufacturers.

Fan manufacturers define a standard cubic foot (0.0283 cubic metres) of air as clean, dry air at an absolute pressure of 14.696 psi (101.325 kPa} and a temperature of 70 °F (21 °C), which amounts to air at a standard density of 0.075 lb/ft³ (1.20 kg/m³). Thus, fan performance tables are based on moving standard air at 70 °F and at an absolute pressure of 14.696 psi, and having a density of 0.075 lb/ft³.[2]

Again, a centrifugal fan is a constant volume device that will move the same amount of air at two different temperatures. Thus, a centrifugal fan that moves 1,000 ft³/min (28 m³/min) at 70 °F (21 °C) will also move 1,000 ft³/min at 200 °F (93 °C). However, since a given volume of 200 °F air weighs much less than the same volume of 70 °F air, the fan will create a lower discharge pressure and will require less driver power.

Thus, for example, when selecting a fan to operate at 200 °F, an air density correction factor must be applied to select the proper size fan to produce a discharge pressure of say ?????. The air density factor is defined as the density of air at the standard temperature of 70 °F to the density of air at the non-standard temperature. In this example, since 200 °F air weighs only 80% of 70 °F air, the air density correction factor is 1.25 (i.e., 1.0 / 0.8).

Air Movement and Control Association (AMCA)

The centrifugal fan performance tables provide the fan RPM and power requirements for the given CFM and static pressure at standard air density. When the centrifugal fan performance is not at standard conditions, the performance must be converted to standard conditions before entering the performance tables. Centrifugal fans rated by the Air Movement and Control Association (AMCA) are tested in laboratories with test setups that simulate installations that are typical for that type of fan. Usually they are tested and rated as one of four standard installation types as designated in AMCA Standard 210.[3]

AMCA Standard 210 defines uniform methods for conducting laboratory tests on housed fans to determine airflow rate, pressure, power and efficiency, at a given speed of rotation. The purpose of AMCA Standard 210 is to define exact procedures and conditions of fan testing so that ratings provided by various manufacturers are on the same basis and may be compared. For this reason, fans must be rated in SCFM.

References

External links

- Air Movement and Control Association website

- Centrifugal Fan Types and Fabrication by Process Barron

- Fan Fundamentals - A brief guide to selecting fans depending on the application by Greenheck Fan corporation

- Temperature and Altitude Affect Fan Selection

- Fan Engineering Data and Selection Guide by Cincinnati Fan