User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 17: | Line 17: | ||

*Exxon Research and Engineering (ERE) | *Exxon Research and Engineering (ERE) | ||

*Shell Global Solutions International | *Shell Global Solutions International | ||

*Stone & Webster Engineering Corporation (SWECO)/Institut Francais Petrole (IFP) | *Stone & Webster Engineering Corporation (SWECO) / Institut Francais Petrole (IFP) | ||

*Universal Oil Products (UOP) | *Universal Oil Products (UOP) | ||

Revision as of 19:54, 24 April 2008

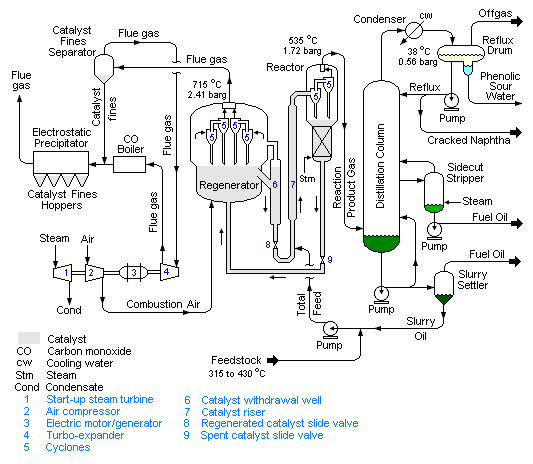

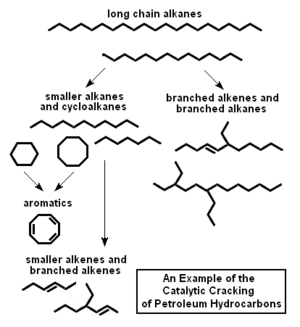

The fluid catalytic cracker (FCC) is the most important conversion process unit used in petroleum refineries. It is widely used to convert the high-boiling hydrocarbon portions of petroleum crude oils to more valuable gasoline, olefinic gases and other products.[1][2][3] The feedstock to an FCC is usually that portion of the crude oil that has an initial boiling point of 330 °C or higher at atmospheric pressure. The FCC process vaporizes and breaks the long-chain molecules of the high-boiling hydrocarbon liquids into much shorter molecules by contacting the feedstock, at a moderate pressure, with a very hot powdered catalyst.

In effect, refineries use fluid catalytic cracking to correct the imbalance between the market demand for gasoline and the excess of heavy, high boiling range products resulting from the distillation of crude oil.

As of 2006, FCC units were in operation at 400 petroleum refineries worldwide and about one-third of the crude oil refined in those refineries is processed in an FCC to produce high-octane gasoline, diesel oil and fuel oil.[2][4] During 2007, the FCC units in the United States processed a total of 834,300,000 litres per day of feedstock[5] and FCC units worldwide processed about twice that amount.

Flow diagram and process description

There are a number of different proprietary designs that have been developed for modern FCC units. Each design is available under a license that must be purchased from the design developer by any petroleum refining company desiring to construct and operate an FCC of a given design.

Basically, there are two different configurations for an FCC unit: the "stacked" type where the the reactor and the regenerator are contained in a single vessel with the reactor above the catalyst regenerator and the "side-by-side" type where the reactor and regenerator are in two separate vessels. These are the major FCC designers and licensors:[3][6]

Side-by-side configuration:

- ABB Lummus Global

- Exxon Research and Engineering (ERE)

- Shell Global Solutions International

- Stone & Webster Engineering Corporation (SWECO) / Institut Francais Petrole (IFP)

- Universal Oil Products (UOP)

Stacked configuration:

- Kellog Brown & Root (KBR)

Chemistry

Catalysts

History

References

- ↑ James H. Gary and Glenn E. Handwerk (2001). Petroleum Refining: Technology and Economics, 4th Edition. CRC Press. ISBN 0-8247-0482-7.

- ↑ 2.0 2.1 James. G. Speight (2006). The Chemistry and Technology of Petroleum, 4th Edition. CRC Press. ISBN 0-8493-9067-2.

- ↑ 3.0 3.1 Reza Sadeghbeigi (2000). Fluid Catalytic Cracking Handbook, 2nd Edition. Gulf Publishing. 0-88415-289-8.

- ↑ David S.J. Jones and Peter P.Pujado (Editors) (2006). Handbook of Petroleum Processing, First Edition. Springer. ISBN 1-4020-2819-9.

- ↑ U.S. Downstream Processing of Fresh Feed Input by Catalytic Cracking Units (Energy Information Administration, U.S. Dept. of Energy)

- ↑ Editorial Staff (November 2002). "Refining Processes 2002". Hydrocarbon Processing: 108-112. ISSN 0887-0284.