User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok No edit summary |

||

| Line 1: | Line 1: | ||

A '''delayed coker''' is a type of [[Coker unit|coker]] whose process consists of heating a [[residual oil]] feed to its [[thermal cracking]] temperature in a [[furnace]] with multiple parallel passes. This cracks the heavy, long chain [[hydrocarbon]] molecules of the residual oil into coker [[gas oil]] and [[petroleum coke]].<ref>{{cite book|author=Gary, J.H. and Handwerk, G.E.|title=Petroleum Refining Technology and Economics|edition=2nd Edition|publisher=Marcel Dekker, Inc|year=1984|id=ISBN 0-8247-7150-8}}</ref><ref>{{cite book|author=Leffler, W.L. |title=Petroleum refining for the nontechnical person|edition=2nd Edition|publisher=PennWell Books|year=1985|id=ISBN 0-87814-280-0}}</ref><ref>[http://www.petcokeconsulting.com/glossary/index.html Petroleum Coke Glossary]</ref> Delayed coking is one of the [[unit processes]] used in many [[Oil refinery|oil refineries]]. | |||

==Description== | |||

[[Cracking (chemistry)|Cracking]] begins in the furnace, continues in the transfer line, and finishes in the coke drum. | |||

As cracking continues in the drum, gas oil and lighter components are generated in vapor phase and separate from the liquid and solids. The drum effluent is vapor only except for any liquid or solids entrainment, and is directed to a [[fractionation column]] where it is separated into the desirable boiling point fractions. Solid coke is deposited in the drum in a porous structure that allows flow through the pores. All solids and uncracked residual liquid produced from the vapor and liquid feed are intended to remain in the drum. | |||

After the drum is full of the solidified coke, the hot mixture from the furnace is switched to a second drum. While the second drum is filling, the full drum is steamed to further reduce hydrocarbon content of the petroleum coke, and then water quenched to cool it. The top and bottom heads of the full coke drum are removed, and the solid petroleum coke is then cut from the coke drum with a high pressure water nozzle, where it falls into a pit, pad, or sluiceway for reclamation to storage. | |||

Larger cokers have several pairs of tandem drums. | |||

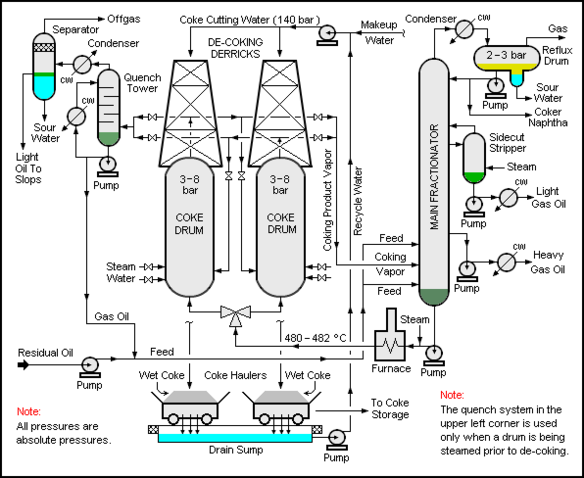

===Typical schematic flow diagram=== | |||

[[Image:Delayed Coker.png|thumb|left|584px|A typical schematic flow diagram of a delayed coking unit]] | |||

==Composition of coke== | |||

The table below illustrates the wide range of compositions for raw petroleum coke (referred to as green coke<ref>[http://goldbook.iupac.org/P04522.html Petroleum coke] on the website of the [[IUPAC]] Compendium of Chemical Terminology</ref>) produced in a delayed coker and the corresponding compositions after the green coke has been calcined at 2375 °F (1302 °C): | |||

<center> | |||

{| class="wikitable" | |||

|+ '''Composition Of Coke From A Delayed Coker''' | |||

! Component!! Green coke<br>as produced!!Coke calcined<br>at 2375 °F | |||

|- | |||

|Fixed carbon, wt %||align="center"|80 − 95 ||align="center"|98.0 − 99.5 | |||

|- | |||

|Hydrogen, wt %||align="center"|3.0 − 4.5 ||align="center"|0.1 | |||

|- | |||

|Nitrogen, wt %||align="center"|0.1 − 0.5 || | |||

|- | |||

|Sulfur, wt %||align="center"|0.2 − 6.0 ||align="center"| | |||

|- | |||

|Volatile matter, wt %||align="center"|5 − 15 ||align="center"|0.2 − 0.8 | |||

|- | |||

|Moisture, wt %||align="center"|0.5 − 10 ||align="center"|0.1 | |||

|- | |||

|Ash, wt %||align="center"|0.1 − 1.0 ||align="center"|0.02 − 0.7 | |||

|- | |||

|Density, g/cc||align="center"|1.2 − 1.6 ||align="center"|1.9 − 2.1 | |||

|- | |||

!Metals, ppm weight:!! !! | |||

|- | |||

| Aluminum||align="center"|15 − 100 ||align="center"|15 − 100 | |||

|- | |||

| Boron||align="center"|0.1 − 15 ||align="center"|0.1 − 15 | |||

|- | |||

| Calcium||align="center"|25 − 500 ||align="center"|25 − 500 | |||

|- | |||

| Chromium||align="center"|5 − 50 ||align="center"|5 − 50 | |||

|- | |||

| Cobalt||align="center"|10 − 60 ||align="center"|10 − 60 | |||

|- | |||

| Iron||align="center"|50 − 5000 ||align="center"|50 − 5000 | |||

|- | |||

| Manganese||align="center"|2 − 100 ||align="center"|2 − 100 | |||

|- | |||

| Magnesium||align="center"|10 − 250 ||align="center"|10 − 250 | |||

|- | |||

| Molybdenum||align="center"|10 − 20 ||align="center"|10 − 20 | |||

|- | |||

| Nickel||align="center"|10 − 500 ||align="center"|10 − 500 | |||

|- | |||

| Potassium||align="center"|20 − 50 ||align="center"|20 − 50 | |||

|- | |||

| Silicon||align="center"|50 − 600 ||align="center"|50 − 600 | |||

|- | |||

| Sodium||align="center"|40 − 70 ||align="center"|40 − 70 | |||

|- | |||

| Titanium||align="center"|2 − 60 ||align="center"|2 − 60 | |||

|- | |||

| Vanadium||align="center"|5 − 500 ||align="center"|5 − 500 | |||

|} | |||

</center> | |||

==See also== | |||

*[[Cracking (chemistry)]] | |||

*[[Shukhov cracking process]] | |||

*[[Burton process]] | |||

*[[Coke (fuel)]] | |||

*[[Visbreaker]] | |||

==References== | |||

{{reflist}} | |||

==External links== | |||

{{Commons|Oil refinery}} | |||

*[http://www.petcokeconsulting.com/glossary/index.html Detailed description of cokers and related topics] | |||

*[http://www.glcarbon.com/pdf/article_delayed.pdf Detailed description of delayed coker] | |||

Revision as of 19:53, 11 February 2008

A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke.[1][2][3] Delayed coking is one of the unit processes used in many oil refineries.

Description

Cracking begins in the furnace, continues in the transfer line, and finishes in the coke drum.

As cracking continues in the drum, gas oil and lighter components are generated in vapor phase and separate from the liquid and solids. The drum effluent is vapor only except for any liquid or solids entrainment, and is directed to a fractionation column where it is separated into the desirable boiling point fractions. Solid coke is deposited in the drum in a porous structure that allows flow through the pores. All solids and uncracked residual liquid produced from the vapor and liquid feed are intended to remain in the drum.

After the drum is full of the solidified coke, the hot mixture from the furnace is switched to a second drum. While the second drum is filling, the full drum is steamed to further reduce hydrocarbon content of the petroleum coke, and then water quenched to cool it. The top and bottom heads of the full coke drum are removed, and the solid petroleum coke is then cut from the coke drum with a high pressure water nozzle, where it falls into a pit, pad, or sluiceway for reclamation to storage.

Larger cokers have several pairs of tandem drums.

Typical schematic flow diagram

Composition of coke

The table below illustrates the wide range of compositions for raw petroleum coke (referred to as green coke[4]) produced in a delayed coker and the corresponding compositions after the green coke has been calcined at 2375 °F (1302 °C):

| Component | Green coke as produced |

Coke calcined at 2375 °F |

|---|---|---|

| Fixed carbon, wt % | 80 − 95 | 98.0 − 99.5 |

| Hydrogen, wt % | 3.0 − 4.5 | 0.1 |

| Nitrogen, wt % | 0.1 − 0.5 | |

| Sulfur, wt % | 0.2 − 6.0 | |

| Volatile matter, wt % | 5 − 15 | 0.2 − 0.8 |

| Moisture, wt % | 0.5 − 10 | 0.1 |

| Ash, wt % | 0.1 − 1.0 | 0.02 − 0.7 |

| Density, g/cc | 1.2 − 1.6 | 1.9 − 2.1 |

| Metals, ppm weight: | ||

| Aluminum | 15 − 100 | 15 − 100 |

| Boron | 0.1 − 15 | 0.1 − 15 |

| Calcium | 25 − 500 | 25 − 500 |

| Chromium | 5 − 50 | 5 − 50 |

| Cobalt | 10 − 60 | 10 − 60 |

| Iron | 50 − 5000 | 50 − 5000 |

| Manganese | 2 − 100 | 2 − 100 |

| Magnesium | 10 − 250 | 10 − 250 |

| Molybdenum | 10 − 20 | 10 − 20 |

| Nickel | 10 − 500 | 10 − 500 |

| Potassium | 20 − 50 | 20 − 50 |

| Silicon | 50 − 600 | 50 − 600 |

| Sodium | 40 − 70 | 40 − 70 |

| Titanium | 2 − 60 | 2 − 60 |

| Vanadium | 5 − 500 | 5 − 500 |

See also

References

- ↑ Gary, J.H. and Handwerk, G.E. (1984). Petroleum Refining Technology and Economics, 2nd Edition. Marcel Dekker, Inc. ISBN 0-8247-7150-8.

- ↑ Leffler, W.L. (1985). Petroleum refining for the nontechnical person, 2nd Edition. PennWell Books. ISBN 0-87814-280-0.

- ↑ Petroleum Coke Glossary

- ↑ Petroleum coke on the website of the IUPAC Compendium of Chemical Terminology