User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok (Needs much more rewording to get rid of Wikipedia characteristic. Also need to reduce the sugar refinery section.) |

||

| Line 1: | Line 1: | ||

A '''refinery''' is an industrial manufacturing facility composed of a group of [[chemical engineering]] [[unit processes]] and [[unit operation]]s used for converting certain raw materials into products of value. | |||

==Types of refineries== | |||

The various types of refineries include: | |||

* [[Petroleum refinery]]: Converts petroleum [[crude oil]] into [[Octane rating|high-octane]] motor fuel ([[gasoline]]/petrol), [[diesel oil]], [[liquefied petroleum gas]]es (LPG), jet aircraft fuel, [[kerosene]], heating [[fuel oil]]s, [[lubricating oil]]s, [[asphalt]] and [[petroleum coke]]. | |||

* [[Sugarcane|Sugar refinery]]: Converts [[sugar cane]] and [[sugar beets]] into crystallized [[sugar]] and sugar syrups. | |||

* [[Natural gas processing]] plant: Purifies and converts raw natural gas into residential, commercial and industrial fuel gas, and also recovers [[natural gas liquids]] (NGL) such as [[ethane]], [[propane]], [[butane]]s and [[pentane]]s. | |||

* [[Salt refinery]]: Converts salt ([[Sodium chloride|NaCl]]), produced by the [[solar evaporation]] of sea water, into crystallized salt used for cooking and for flavoring of food. | |||

* Various metal refineries converting metallic ores into end product metals such as [[alumina]], [[copper]], [[gold]], [[lead]], [[nickel]], [[silver]], [[uranium]], and [[zinc]]. | |||

* [[Vegetable oil refinery]] | |||

==A typical petroleum refinery== | |||

{{main|Petroleum refining processes}} | |||

{{Image|Petroleum refinery.jpg|right|275px|A petroleum refinery.}} | {{Image|Petroleum refinery.jpg|right|275px|A petroleum refinery.}} | ||

{{Image| | |||

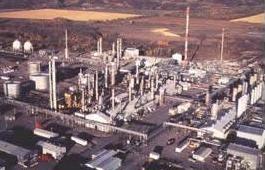

{{Image|Cut sugar cane.jpg|right| | Petroleum refineries are very large industrial complexes that involve a great many different processing units and auxiliary facilities such as utility units and storage tanks. Each refinery has its own unique arrangement and combination of refining processes largely determined by the refinery location, desired products and economic considerations. There are most probably no two refineries that are identical in every respect. | ||

{{Image|Sugar Cane Refinery.png|right| | |||

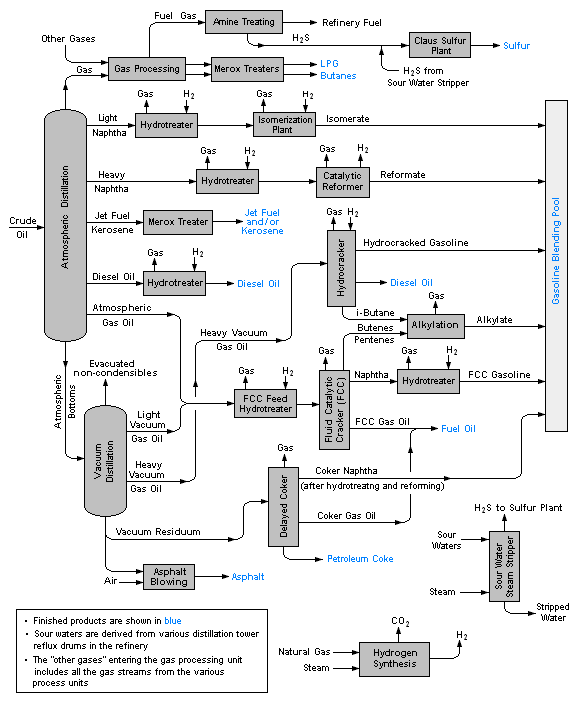

The image below is a schematic [[Process flow diagram|flow diagram]] of a typical oil refinery that depicts the various [[unit]] processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. The diagram depicts only one of the literally hundreds of different oil refinery configurations. It does not include any of the usual refinery facilities providing utilities such as steam, cooling water, and electric power as well as storage tanks for crude oil feedstock and for intermediate products and end products.<ref>{{cite book|author=Gary, J.H. and Handwerk, G.E.|title=Petroleum Refining Technology and Economics|edition=2nd Edition|publisher=Marcel Dekker, Inc|year=1984|isbn=0-8247-7150-8}}</ref><ref>[http://www.chevron.com/products/prodserv/fuels/bulletin/motorgas/3_refining-testing/pg2.asp Guide to Refining] from [[Chevron Corporation|Chevron Oil]]'s website</ref><ref>[http://www.uop.com/refining/1010.html Refinery flowchart] from [[UOP LLC|Universal Oil Products]]' website</ref><ref>[http://www.cheresources.com/refining15.gif An example flowchart] of fractions from crude oil at a refinery</ref> | |||

[[Image:RefineryFlow.png|frame|center|Schematic flow diagram of a typical oil refinery]] | |||

==A typical natural gas processing plant== | |||

[[Image:NaturalGasProcessingPlant.jpg|thumb|310px|right|A natural gas processing plant]] | |||

{{main|Natural gas processing}} | |||

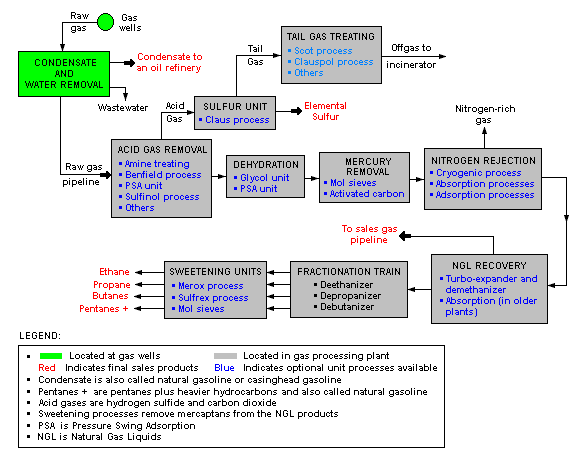

The image below is a schematic [[Process flow diagram|block flow diagram]] of a typical natural gas processing plant. It shows the various unit processes used to convert raw natural gas into sales gas pipelined to the end user markets. | |||

The block flow diagram also shows how processing of the raw natural gas yields byproduct sulfur, byproduct ethane, and natural gas liquids (NGL) propane, butanes and natural gasoline (denoted as pentanes +).<ref>[http://www.eia.doe.gov/pub/oil_gas/natural_gas/feature_articles/2006/ngprocess/ngprocess.pdf ''Natural Gas Processing: The Crucial Link Between Natural Gas Production and Its Transportation to Market'']</ref><ref>[http://www.uop.com/gasprocessing/6070.html ''Example Gas Plant'']</ref><ref>[http://www.axens.net/upload/presentations/fichier/axens_gpagcc_2004v2.pdf ''From Purification to Liquefaction Gas Processing'']</ref><ref>[http://www.spe.org/specma/binary/files/5804785Syn10682.pdf ''Feed-Gas Treatment Design for the Pearl GTL Project'']</ref><ref>[http://lnglicensing.conocophillips.com/NR/rdonlyres/B78B6727-E5F4-4505-B9C3-96CC94D7B30D/7357/AICHELNGNGLIntegrationPaper.pdf ''Benefits of integrating NGL extraction and LNG liquefaction'']</ref> | |||

[[Image:NatGasProcessing.png|frame|center|Schematic flow diagram of a typical natural gas processing plant]] | |||

{{Image|Cut sugar cane.jpg|right|300px|Cut sugar cane.}} | |||

{{Image|Sugar Refinery 1.jpg|right|300px|A sugar refinery in [[New South Wales]], [[Australia.]]}} | |||

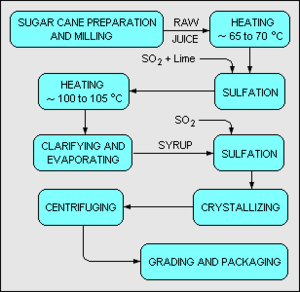

{{Image|Sugar Cane Refinery.png|right|300px|Flow diagram of sugar refining process.}} | |||

==Typical refining of sugar== | |||

Most of the sugar produced worldwide is derived either from [[sugarcane]] or [[sugar beet]]s. However, the sugar produced from sugarcane is at least twice the amount produced by sugar beets. For that reason, this section on the refining of sugar deals with sugar produced from sugarcane. | |||

The refining of sugarcane into sugar has traditionally been done in two stages. The first stage is the production of a raw sugar by the milling of freshly harvested sugarcane, usually done locally in the sugarcane-producing regions. In a sugar mill, sugarcane is washed, chopped, and shredded by revolving knives. The shredded cane is mixed with water and crushed. The juices (containing 10-15 percent [[sucrose]]) are collected and mixed with [[lime (mineral)|lime]] to adjust its [[pH]] to 7 which arrests sucrose's decay into [[glucose]] and [[fructose]], and precipitates out some impurities. The lime and other suspended solids are settled out, and the clarified juice is concentrated in a [[multiple-effect evaporator]] to make a syrup with about 60 weight percent sucrose. The syrup is further concentrated under [[vacuum]] until it becomes [[supersaturated]], and then seeded with [[crystalline]] sugar. Upon cooling, sugar crystallizes out of the syrup. [[Centrifuge|Centrifuginging]] then separates the sugar from the remaining liquid (molasses). Raw sugar has a yellow to brown color. To produce a white sugar, [[sulfur dioxide]] is bubbled through the cane juice before evaporation so as to bleach color-forming impurities into colourless ones. Sugar bleached white by this means is called ''mill white'', ''plantation white'', and ''crystal sugar''. It is the form of sugar most often consumed in the sugarcane-producing countries. | |||

The fibrous solids, called ''bagasse'', remaining after the crushing of the shredded sugarcane, are burned for fuel which makes a sugar mill more than self-sufficient in energy. Any surplus bagasse can be used for animal feed, in paper manufacture, or burned to generate electricity for the local power grid. | |||

The second stage is the processing is done in sugar refineries, often located in heavy sugar-consuming regions such as [[North America]], [[Europe]], and [[Japan]], to produce refined white sugar that is more than 99 percent pure [[sucrose]]. In such refineries, raw sugar is further purified. It is first mixed with heavy syrup and centrifuged to wash away the outer coating of the raw sugar crystals, which is less pure than the crystal interior. The remaining sugar is then dissolved to make a syrup (about 70 percent by weight solids) which is clarified by the addition of [[phosphoric acid]] and [[calcium hydroxide]] that combine to precipitate [[calcium phosphate]]. The calcium phosphate particles entrap some impurities and absorb others, and then float to the top of the tank, where they are skimmed off. | |||

After any remaining solids are filtered out, the clarified syrup is decolorized by filtration through a bed of [[activated carbon]]. The purified syrup is then concentrated to supersaturation and repeatedly crystallized under vacuum to produce [[white refined sugar]]. As in a sugar mill, the sugar crystals are separated from the molasses by centrifuging. To produce [[granulated sugar]], in which the individual sugar grains do not clump together, sugar must be dried. Drying is accomplished first by drying the sugar in a hot rotary dryer, and then by blowing cool air through it for several days. | |||

==The equipment used in refineries== | |||

Refineries utilize a great many different types of physical equipment such as: | |||

* [[Centrifugation|Centrifuges]] | |||

* [[Gas compressor|Compressors]] | |||

* [[Cooling tower]]s | |||

* Crushers | |||

* [[Crystallization processes|Crystallizers]] | |||

* [[Distillation|Distillation towers]] and [[Pressure vessel|other pressure vessels]] | |||

* [[Electrical generators|Electric power generators]], [[transformer]]s and [[electric motors]] | |||

* [[Electrolysis]] cells | |||

* [[Evaporation|Evaporators]] | |||

* [[filter (chemistry)|Filters]] | |||

* [[Furnaces]] | |||

* [[Gas flare]]s | |||

* [[Mixture|Mixers]] and blenders | |||

* [[Control system|Monitoring and control systems]] | |||

* [[Piping]] and [[valves]] | |||

* [[Pumps]] | |||

* [[Steam generator]]s | |||

* [[Steam turbine]]s and [[gas turbine]]s | |||

* [[Storage tank]]s | |||

* [[Industrial water treatment|Wastewater treatment]] | |||

==See also== | |||

* [[Aluminium oxide|Alumina]] | |||

* [[Bagasse]] | |||

* [[Bayer process]] and [[Hall-Héroult process]] (used to produce aluminium from bauxite ore) | |||

* [[Falconbridge Ltd.]] (large mining and metals refining company) | |||

* [[Liquefied Natural Gas]] (LNG) | |||

* [[LPG|Liquefied petrolem gas]] (LPG) | |||

* [[Natural gas]] | |||

* [[Oil refinery]] | |||

* [[Petroleum]] | |||

* [[Sugarcane|Sugar cane]] | |||

* [[Sugar beet]] | |||

==References== | |||

<references/> | |||

==External links== | |||

* [http://www.osha.gov/dts/osta/otm/otm_iv/otm_iv_2.html Complete, detailed oil refinery description] | |||

* [http://www.naturalgas.org/naturalgas/processing_ng.asp Processing natural gas] | |||

* [http://www.sucrose.com/learn.html Aluminum production process flow sheets] | |||

* [http://www.worldlpgas.com World LP Gas Association] | |||

* [http://www.npga.org/i4a/pages/index.cfm?pageid=1 National Propane Gas Association, USA]] | |||

* [http://www.ferc.gov/for-citizens/lng.asp Liquefied Natural Gas (LNG) Overview] | |||

* [http://www.sucrose.com/learn.html Making sugar] | |||

* [http://www.ussugar.com/sugar/sugar_refining.pdf Sugar refining] | |||

* [http://www.energysupplylogistics.com/refineries Searchable United States Refinery Map] | |||

* [http://www.energyinst.org.uk/education/refineries/map.htm Interactive map of UK refineries] | |||

Revision as of 22:19, 13 January 2009

A refinery is an industrial manufacturing facility composed of a group of chemical engineering unit processes and unit operations used for converting certain raw materials into products of value.

Types of refineries

The various types of refineries include:

- Petroleum refinery: Converts petroleum crude oil into high-octane motor fuel (gasoline/petrol), diesel oil, liquefied petroleum gases (LPG), jet aircraft fuel, kerosene, heating fuel oils, lubricating oils, asphalt and petroleum coke.

- Sugar refinery: Converts sugar cane and sugar beets into crystallized sugar and sugar syrups.

- Natural gas processing plant: Purifies and converts raw natural gas into residential, commercial and industrial fuel gas, and also recovers natural gas liquids (NGL) such as ethane, propane, butanes and pentanes.

- Salt refinery: Converts salt (NaCl), produced by the solar evaporation of sea water, into crystallized salt used for cooking and for flavoring of food.

- Various metal refineries converting metallic ores into end product metals such as alumina, copper, gold, lead, nickel, silver, uranium, and zinc.

- Vegetable oil refinery

A typical petroleum refinery

Petroleum refineries are very large industrial complexes that involve a great many different processing units and auxiliary facilities such as utility units and storage tanks. Each refinery has its own unique arrangement and combination of refining processes largely determined by the refinery location, desired products and economic considerations. There are most probably no two refineries that are identical in every respect.

The image below is a schematic flow diagram of a typical oil refinery that depicts the various unit processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. The diagram depicts only one of the literally hundreds of different oil refinery configurations. It does not include any of the usual refinery facilities providing utilities such as steam, cooling water, and electric power as well as storage tanks for crude oil feedstock and for intermediate products and end products.[1][2][3][4]

A typical natural gas processing plant

The image below is a schematic block flow diagram of a typical natural gas processing plant. It shows the various unit processes used to convert raw natural gas into sales gas pipelined to the end user markets.

The block flow diagram also shows how processing of the raw natural gas yields byproduct sulfur, byproduct ethane, and natural gas liquids (NGL) propane, butanes and natural gasoline (denoted as pentanes +).[5][6][7][8][9]

Typical refining of sugar

Most of the sugar produced worldwide is derived either from sugarcane or sugar beets. However, the sugar produced from sugarcane is at least twice the amount produced by sugar beets. For that reason, this section on the refining of sugar deals with sugar produced from sugarcane.

The refining of sugarcane into sugar has traditionally been done in two stages. The first stage is the production of a raw sugar by the milling of freshly harvested sugarcane, usually done locally in the sugarcane-producing regions. In a sugar mill, sugarcane is washed, chopped, and shredded by revolving knives. The shredded cane is mixed with water and crushed. The juices (containing 10-15 percent sucrose) are collected and mixed with lime to adjust its pH to 7 which arrests sucrose's decay into glucose and fructose, and precipitates out some impurities. The lime and other suspended solids are settled out, and the clarified juice is concentrated in a multiple-effect evaporator to make a syrup with about 60 weight percent sucrose. The syrup is further concentrated under vacuum until it becomes supersaturated, and then seeded with crystalline sugar. Upon cooling, sugar crystallizes out of the syrup. Centrifuginging then separates the sugar from the remaining liquid (molasses). Raw sugar has a yellow to brown color. To produce a white sugar, sulfur dioxide is bubbled through the cane juice before evaporation so as to bleach color-forming impurities into colourless ones. Sugar bleached white by this means is called mill white, plantation white, and crystal sugar. It is the form of sugar most often consumed in the sugarcane-producing countries.

The fibrous solids, called bagasse, remaining after the crushing of the shredded sugarcane, are burned for fuel which makes a sugar mill more than self-sufficient in energy. Any surplus bagasse can be used for animal feed, in paper manufacture, or burned to generate electricity for the local power grid.

The second stage is the processing is done in sugar refineries, often located in heavy sugar-consuming regions such as North America, Europe, and Japan, to produce refined white sugar that is more than 99 percent pure sucrose. In such refineries, raw sugar is further purified. It is first mixed with heavy syrup and centrifuged to wash away the outer coating of the raw sugar crystals, which is less pure than the crystal interior. The remaining sugar is then dissolved to make a syrup (about 70 percent by weight solids) which is clarified by the addition of phosphoric acid and calcium hydroxide that combine to precipitate calcium phosphate. The calcium phosphate particles entrap some impurities and absorb others, and then float to the top of the tank, where they are skimmed off.

After any remaining solids are filtered out, the clarified syrup is decolorized by filtration through a bed of activated carbon. The purified syrup is then concentrated to supersaturation and repeatedly crystallized under vacuum to produce white refined sugar. As in a sugar mill, the sugar crystals are separated from the molasses by centrifuging. To produce granulated sugar, in which the individual sugar grains do not clump together, sugar must be dried. Drying is accomplished first by drying the sugar in a hot rotary dryer, and then by blowing cool air through it for several days.

The equipment used in refineries

Refineries utilize a great many different types of physical equipment such as:

- Centrifuges

- Compressors

- Cooling towers

- Crushers

- Crystallizers

- Distillation towers and other pressure vessels

- Electric power generators, transformers and electric motors

- Electrolysis cells

- Evaporators

- Filters

- Furnaces

- Gas flares

- Mixers and blenders

- Monitoring and control systems

- Piping and valves

- Pumps

- Steam generators

- Steam turbines and gas turbines

- Storage tanks

- Wastewater treatment

See also

- Alumina

- Bagasse

- Bayer process and Hall-Héroult process (used to produce aluminium from bauxite ore)

- Falconbridge Ltd. (large mining and metals refining company)

- Liquefied Natural Gas (LNG)

- Liquefied petrolem gas (LPG)

- Natural gas

- Oil refinery

- Petroleum

- Sugar cane

- Sugar beet

References

- ↑ Gary, J.H. and Handwerk, G.E. (1984). Petroleum Refining Technology and Economics, 2nd Edition. Marcel Dekker, Inc. ISBN 0-8247-7150-8.

- ↑ Guide to Refining from Chevron Oil's website

- ↑ Refinery flowchart from Universal Oil Products' website

- ↑ An example flowchart of fractions from crude oil at a refinery

- ↑ Natural Gas Processing: The Crucial Link Between Natural Gas Production and Its Transportation to Market

- ↑ Example Gas Plant

- ↑ From Purification to Liquefaction Gas Processing

- ↑ Feed-Gas Treatment Design for the Pearl GTL Project

- ↑ Benefits of integrating NGL extraction and LNG liquefaction

External links

- Complete, detailed oil refinery description

- Processing natural gas

- Aluminum production process flow sheets

- World LP Gas Association

- National Propane Gas Association, USA]

- Liquefied Natural Gas (LNG) Overview

- Making sugar

- Sugar refining

- Searchable United States Refinery Map

- Interactive map of UK refineries