User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok |

||

| Line 76: | Line 76: | ||

|} | |} | ||

|} | |} | ||

In the past, natural gas was almost always a byproduct of [[Oil well|producing oil]], since the small, light gas carbon chains come out of solution as it undergoes pressure reduction from the [[Petroleum reservoir|reservoir]] to the surface, similar to uncapping a bottle of soda pop where the carbon dioxide [[effervesce]]s. Unwanted natural gas can be a disposal problem at the well site. If there is not a market for natural gas near the [[wellhead]] it is virtually valueless since it must be piped to the end user. Until recently, such unwanted gas was burned off at the wellsite, but due to environmental concerns this practice is becoming less common. Often, unwanted (or 'stranded' gas without a market) gas is pumped back into the reservoir with an 'injection' well for disposal or repressurizing the producing formation. Another solution is to export the natural gas as | In the past, natural gas was almost always a byproduct of [[Oil well|producing oil]], since the small, light gas carbon chains come out of solution as it undergoes pressure reduction from the [[Petroleum reservoir|reservoir]] to the surface, similar to uncapping a bottle of soda pop where the carbon dioxide [[effervesce]]s. Unwanted natural gas can be a disposal problem at the well site. If there is not a market for natural gas near the [[wellhead]] it is virtually valueless since it must be piped to the end user. Until recently, such unwanted gas was burned off at the wellsite, but due to environmental concerns this practice is becoming less common. Often, unwanted (or 'stranded' gas without a market) gas is pumped back into the reservoir with an 'injection' well for disposal or repressurizing the producing formation. Another solution is to export the natural gas as liquefied natural gas {{LNG]]. Gas-to-liquid (GTL) is a developing technology that converts natural gas into synthetic gasoline, diesel or jet fuel through the [[Fischer-Tropsch]] process developed in World War II Germany. Such fuels can be transported through conventional pipelines and tankers to users. Proponents claim GTL fuels burn cleaner than comparable petroleum fuels. Most major international oil companies are in advanced development stages of GTL production, with a world-scale (140,000 bbl/day) GTL plant in Qatar scheduled to come online before 2010. In locations such as the United States with a high natural gas demand, pipelines are constructed to take the gas from the wellsite to the [[end consumer]]. | ||

Fossil natural gas can be "associated" (found in [[oil field]]s) or "non-associated" (isolated in [[natural gas field]]s), and is also found in [[coal bed]]s (as [[coalbed methane]]). It sometimes contains significant quantities of [[ethane]], [[propane]], [[butane]], and [[pentane]]—heavier hydrocarbons removed prior to use as a consumer fuel—as well as [[carbon dioxide]], [[nitrogen]], [[helium]] and [[hydrogen sulfide]].<ref>[http://www.naturalgas.org/overview/background.asp Natural gas overview]</ref> | Fossil natural gas can be "associated" (found in [[oil field]]s) or "non-associated" (isolated in [[natural gas field]]s), and is also found in [[coal bed]]s (as [[coalbed methane]]). It sometimes contains significant quantities of [[ethane]], [[propane]], [[butane]], and [[pentane]]—heavier hydrocarbons removed prior to use as a consumer fuel—as well as [[carbon dioxide]], [[nitrogen]], [[helium]] and [[hydrogen sulfide]].<ref>[http://www.naturalgas.org/overview/background.asp Natural gas overview]</ref> | ||

Revision as of 23:37, 17 September 2009

Natural gas is a gas consisting primarily of methane (CH4). It is found as raw natural gas in underground reservoirs, as gas associated with underground reservoirs of petroleum crude oil, as methane hydrates and as coalbed methane in underground coal mines. It is an important fuel source and a major feedstock for producing ammonia, hydrogen, petrochemicalsand fertilizers.

Natural gas is often informally referred to as simply gas or fuel gas, especially when compared to other energy sources such as electricity.

There are a great many different natural gas reservoirs worldwide and each of those gas deposits has a different composition. However, in general, most of them contain at least 90 volume percent of methane. Before raw natural gas from extracted from those reservoirs can be used as a fuel, it must undergo extensive processing to remove almost all materials other than methane. The by-products of that processing include ethane, propane, butanes, natural gasoline (referred to as pentanes +) and higher molecular weight hydrocarbons, elemental sulfur, and sometimes helium and nitrogen.

Formation of natural gas

While the origins of natural gas deposits are not known with certainty, and the different reservoirs vary in their geologic history, it is generally believed[1][2] that the gas is formed over millions of years from organic matter, usually from former marine or coastal ecosystems. Decomposed organic matter from dead plants and animals became covered in layers of mud and other sediments, and as more mud and other sediments piled on top of the organic matter, the pressure and temperature increased. The increased pressure and temperature is thought to have caused the organic matter to slowly transform into natural gas and oil. Once formed, gas deposits tended to rise towards the surface of the earth through fissures and pores, until they become trapped underneath less permeable rock layers and formed gas reservoirs.

Finding and extracting natural gas

- Exploration

Exploration, in the oil and gas industry, is the search for natural gas reservoirs. Recoverable reserves of natural gas tend to occur where impermeable rocks (called caprocks) constrain the upward movement of gas through the undergound soil and rocks. Geologists and geophysicists usually use seismology to find areas which have the right conditions for a gas or oil deposit. High-speed computers that help develop three-dimensional underground maps as well as satellite image technology are also widely used to search for natural gas reservoirs.

- Extraction

After an initial exploration, wells are drilled to confirm the existence of a reservoir and its size. Once a resevoir of natural gas has been confirmed, production wells are drilled to extract the gas. Once reached by a well, the gas comes up to the surface under its own pressure.

Over time, the gas flow rate decreases, but may be maintained by drilling reinjection wells and using gas compressors to reinject compressed gas downward into the reservoir.

Composition of raw natural gas

Raw natural gas typically consists primarily of methane (CH4), the shortest and lightest hydrocarbon molecule. It also contains varying amounts of:

- Heavier gaseous hydrocarbons: ethane (C2H6), propane (C3H8), normal butane (n-C4H10), isobutane (i-C4H10), pentanes and even higher molecular weight hydrocarbons. When processed and purified into finished by-products, all of these are collectively referred to as NGL (Natural Gas Liquids).

- Acid gases: carbon dioxide (CO2), hydrogen sulfide (H2S) and mercaptans such as methanethiol (CH3SH) and ethanethiol (C2H5SH).

- Other gases: nitrogen (N2) and helium (He).

- Water: water vapor and liquid water.

- Liquid hydrocarbons: perhaps some natural gas condensate (also referred to as casinghead gasoline or natural gasoline) and/or crude oil.

- Mercury: very small amounts of mercury primarily in elemental form, but chlorides and other species are possibly present.[3]

Measurement units and heating values

Quantities of natural gas are measured in normal cubic meters at 0 °C and 101.325 kPa absolute pressure or in standard cubic feet at 60 °F and 14.496 psi absolute pressure.[4]

The higher heating value (HHV)[5] of commercial, processed natural gas is about 40 MJ per normal cubic meter which, in the United States, is equivalent to about 1,015 Btu per standard cubic foot. However, those values can vary by several percent from one natural gas to another depending upon their source reservoir and upon their degree of processing.

The heating value of a fuel gas when the water formed during combustion does not condense is the called the lower heating value (LHV)[6] and can be as much as 10% less than the HHV.

In the United States, the retail sales processed natural gas to end users are often in units of therms with 1 therm being 100,000 Btu (equivalent to the higher heating value of roughly 100 standard cubic feet).

Sources

| ||||||||||||||||||||||||||||

In the past, natural gas was almost always a byproduct of producing oil, since the small, light gas carbon chains come out of solution as it undergoes pressure reduction from the reservoir to the surface, similar to uncapping a bottle of soda pop where the carbon dioxide effervesces. Unwanted natural gas can be a disposal problem at the well site. If there is not a market for natural gas near the wellhead it is virtually valueless since it must be piped to the end user. Until recently, such unwanted gas was burned off at the wellsite, but due to environmental concerns this practice is becoming less common. Often, unwanted (or 'stranded' gas without a market) gas is pumped back into the reservoir with an 'injection' well for disposal or repressurizing the producing formation. Another solution is to export the natural gas as liquefied natural gas {{LNG]]. Gas-to-liquid (GTL) is a developing technology that converts natural gas into synthetic gasoline, diesel or jet fuel through the Fischer-Tropsch process developed in World War II Germany. Such fuels can be transported through conventional pipelines and tankers to users. Proponents claim GTL fuels burn cleaner than comparable petroleum fuels. Most major international oil companies are in advanced development stages of GTL production, with a world-scale (140,000 bbl/day) GTL plant in Qatar scheduled to come online before 2010. In locations such as the United States with a high natural gas demand, pipelines are constructed to take the gas from the wellsite to the end consumer.

Fossil natural gas can be "associated" (found in oil fields) or "non-associated" (isolated in natural gas fields), and is also found in coal beds (as coalbed methane). It sometimes contains significant quantities of ethane, propane, butane, and pentane—heavier hydrocarbons removed prior to use as a consumer fuel—as well as carbon dioxide, nitrogen, helium and hydrogen sulfide.[9] Natural gas is commercially produced from oil fields and natural gas fields. Gas produced from oil wells is called casinghead gas or associated gas. The natural gas industry is producing gas from increasingly more challenging resource types: sour gas, tight gas, shale gas and coalbed methane.

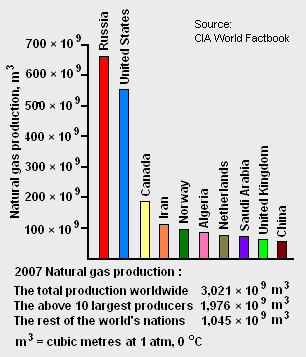

The world's largest proven gas reserves are located in Russia, with 4.757 × 1013 cubic metres. Russia is also the world's largest natural gas producer, through the Gazprom company. Major proven resources (with year of estimate) (in billion cubic metres) are world 175,400 (2006), Russia 47,570 (2006), Iran 26,370 (2006), Qatar 25,790 (2007), Saudi Arabia 6,568 (2006) and United Arab Emirates 5,823 (2006).

The world's largest gas field is the offshore North Field in Qatar, estimated to have 25 trillion cubic metres of gas in place — enough to last more than 200 years at optimum production levels. The second largest natural gas field is the South Pars Gas Field in Iranian waters in the Persian Gulf. Connected to Qatar's North Field, it has estimated reserves of 8 to 14 trillion cubic metres.[10]

Because natural gas is not a pure product, when non-associated gas is extracted from a field under supercritical (pressure/temperature) conditions, it may partially condense upon isothermic depressurizing—an effect called retrograde condensation. The liquids thus formed may get trapped by depositing in the pores of the gas reservoir. One method to deal with this problem is to reinject dried gas free of condensate to maintain the underground pressure and to allow reevaporation and extraction of condensates.

Landfill gas is created from the decomposition of waste in landfills. If the gas is not removed, the pressure may get so high that it works its way to the surface, causing damage to the landfill structure, unpleasant odor, vegetation die-off and an explosion hazard. The gas can be vented to the atmosphere, flared or burned to produce electricity or heat. Experimental systems were being proposed for use in parts Hertfordshire, UK and Lyon in France.

Once water vapor is removed, about half of landfill gas is methane. Almost all of the rest is carbon dioxide, but there are also small amounts of nitrogen, oxygen and hydrogen. There are usually trace amounts of hydrogen sulfide and siloxanes, but their concentration varies widely. Landfill gas cannot be distributed through natural gas pipelines unless it is cleaned up to the same quality. It is usually more economical to combust the gas on site or within a short distance of the landfill using a dedicated pipeline. Water vapor is often removed, even if the gas is combusted on site. If low temperatures condense water out of the gas, siloxanes can be lowered as well because they tend to condense out with the water vapor. Other non-methane components may also be removed in order to meet emission standards, to prevent fouling of the equipment or for environmental considerations. Co-firing landfill gas with natural gas improves combustion, which lowers emissions.

Huge quantities of natural gas (primarily methane) exist in the form of hydrates under sediment on offshore continental shelves and on land in arctic regions that experience permafrost such as those in Siberia (hydrates require a combination of high pressure and low temperature to form). However, Template:As of no technology has been developed to produce natural gas economically from hydrates.

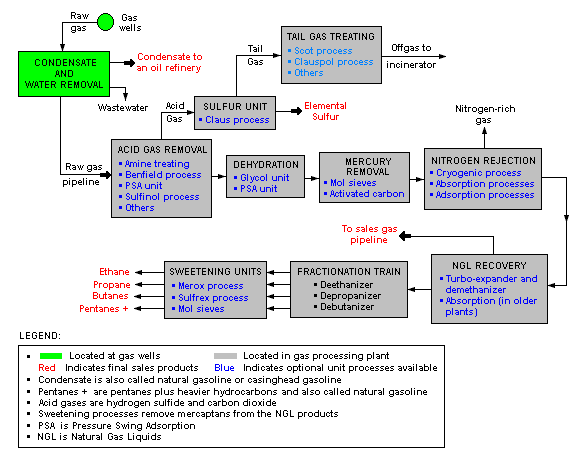

Natural gas processing

There are a great many ways in which to configure the various unit processes used in the processing of raw natural gas. The schematic block flow diagram below is a generalized, typical configuration for the processing of raw natural gas from non-associated gas wells. It shows how raw natural gas is processed into sales gas pipelined to the end user markets.[11][12][13]

The block flow diagram also shows how processing of the raw natural gas yields these byproducts:

- Natural gas condensate

- Sulfur

- Ethane

- Natural gas liquids (NGL): propane, butanes and C5+ (which is the commonly used term for pentanes plus higher molecular weight hydrocarbons)

Uses of natural gas

- Power generation

Natural gas is a major source of electricity generation through the use of gas turbines and steam turbines. Most grid peaking power plants and some off-grid engine-generators use natural gas. Particularly high efficiencies can be achieved through combining gas turbines with a steam turbine in combined cycle mode. Natural gas burns more cleanly than other fossil fuels, such as oil and coal, and produces less carbon dioxide per unit energy released. For an equivalent amount of heat, burning natural gas produces about 30% less carbon dioxide than burning petroleum and about 45% less than burning coal.[14] Combined cycle power generation using natural gas is thus the cleanest source of power available using fossil fuels, and this technology is widely used wherever gas can be obtained at a reasonable cost. Fuel cell technology may eventually provide cleaner options for converting natural gas into electricity, but as yet it is not price-competitive. (Please note: some algal fuel producers are considering feeding the carbon dioxide resulting from natural gas burning to algae to promote growth.)

- Domestic use

Natural gas is supplied to homes, where it is used for such purposes as cooking in natural gas-powered ranges and/or ovens, natural gas-heated clothes dryers, heating/cooling and central heating. Home or other building heating may include boilers, furnaces, and water heaters. CNG is used in rural homes without connections to piped-in public utility services, or with portable grills. However, due to CNG being less economical than LPG, LPG (Propane) is the dominant source of rural gas.

- Transportation fuel

Compressed natural gas (methane) is a cleaner alternative to other automobile fuels such as gasoline (petrol) and diesel oil. As of December 2008, the countries with the highest number of CNG vehicles, ranked numerically, were Pakistan [15], Argentina, Brazil, Iran and India. The energy efficiency is generally equal to that of gasoline engines, but lower compared with modern diesel engines. Gasoline/petrol vehicles converted to run on natural gas suffer because of the low compression ratio of their engines, resulting in a cropping of delivered power while running on natural gas (10%-15%). CNG-specific engines, however, use a higher compression ratio due to this fuel's higher octane number of 120–130.[16]

- Fertilizer

Natural gas is a major feedstock for the production of ammonia, via the Haber process, for use in fertilizer production.

- Hydrogen

Natural gas is also a major feedstock for the production of hydrogen, with one common method being the steam-methane reformer (SMR). Hydrogen has various applications: it is a primary feedstock for the chemical industry, a hydrogenating agent, an important commodity for oil refineries, and a fuel source in hydrogen vehicles.

- Aviation

Russian aircraft manufacturer Tupolev is currently running a development program to produce LNG- and hydrogen-powered aircraft.[17] The program has been running since the mid-1970s, and seeks to develop LNG and hydrogen variants of the Tu-204 and Tu-334 passenger aircraft, and also the Tu-330 cargo aircraft.

The advantages of liquid methane as a jet engine fuel are that it has more specific energy than the standard kerosene mixes and that its low temperature can help cool the air which the engine compresses for greater volumetric efficiency, in effect replacing an intercooler. Alternatively, it can be used to lower the temperature of the exhaust.

- Other

Natural gas is used as a feedstock in the production of petrochemicals.

Storage and transport

The major difficulty in the use of natural gas is transportation and storage because of its low density. Natural gas pipelines are economical, but are impractical across oceans. Many existing pipelines in North America are close to reaching their capacity, prompting some politicians representing colder areas to speak publicly of potential shortages. In Europe gas pipeline network is already dense in the West[18]. New pipelines are planned or under construction in the Eastern Europe and between gas fields in Russia, Near East and Northern Africa and Western Europe. (See also: List of natural gas pipelines )

LNG carriers can be used to transport liquefied natural gas (LNG) across oceans, while tank trucks can carry liquefied or compressed natural gas (CNG) over shorter distances. Sea transport using CNG carrier ships that are now under development may be competitive with LNG transport in specific conditions.

For LNG transport a liquefaction plant is needed at the exporting end and regasification equipment at the receiving terminal. Shipborne regasification equipment is also practicable. LNG transportation is established as the preferred technology for long distance, high volume transportation of natural gas, whereas pipeline transport is preferred for transport for distances up to typically 4.000 km overland and approximately half that distance over seas.

For CNG transport high pressure, typically above 200 bars, is used. Compressors and decompression equipment are less capital intensive and may be economical in smaller unit sizes than liquefaction/regasification plants. For CNG mode the crucial problem is the investment and operating cost of carriers. Natural gas trucks and carriers may transport natural gas directly to end-users, or to distribution points such as pipelines for further transport.

In the past, the natural gas which was recovered in the course of recovering petroleum could not be profitably sold, and was simply burned at the oil field (known as flaring). This wasteful practice is now illegal in many countries[19]. Additionally, companies now recognize that value for the gas may be achieved with LNG, CNG, or other transportation methods to end-users in the future. The gas is now re-injected back into the formation for later recovery. This also assists oil pumping by keeping underground pressures higher. In Saudi Arabia, in the late 1970s, a "Master Gas System" was created, ending the need for flaring. Satellite observation unfortunately shows that some large gas-producing countries still use flaring[20] and venting[21] routinely. The natural gas is used to generate electricity and heat for desalination. Similarly, some landfills that also discharge methane gases have been set up to capture the methane and generate electricity.

Natural gas is often stored underground inside depleted gas reservoirs from previous gas wells, salt domes, or in tanks as liquefied natural gas. The gas is injected during periods of low demand and extracted during periods of higher demand. Storage near the ultimate end-users helps to best meet volatile demands, but this may not always be practicable.

With 15 nations accounting for 84% of the worldwide production, access to natural gas has become a significant factor in international economics and politics. In this respect, control over the pipelines is a major strategic factor.[22] In particular, in the 2000s, Gazprom, the Russian national energy company, has engaged in disputes with Ukraine and Belarus over the price of its natural gas, which have created worries that gas deliveries to parts of Europe could be cut off for political reasons.[23]

Environmental effects

The use of natural gas as combustion fuel produces far less emissions of air pollutants such as sulfur dioxide and nitrogen oxides than does the combustion of coal or fuel oils. However, in it does contribute significantly to global carbon dioxide emissions. According to the IPCC Fourth Assessment Report, in 2004 natural gas produced about 5,300 Mt/yr of CO2 emissions, while coal and oil produced 10,600 and 10,200 respectively.

In addition, natural gas is a greenhouse gas more potent than carbon dioxide when released into the atmosphere. It is inevitable that, in using natural gas as a combustion fuel on a large scale, some of it will leak into the atmosphere. However, it is not of large concern due to the small amounts of such leakage. Carbon dioxide receives the the most attention over greenhouse gases because it is in much higher concentrations.

Safety

In any form, a minute amount of odorant such as t-butyl mercaptan, with a rotting-cabbage-like smell, is added to the otherwise colorless and almost odorless gas, so that leaks can be detected before a fire or explosion occurs. Sometimes a related compound, thiophane is used, with a rotten-egg smell. Adding odorant to natural gas began in the United States after the 1937 New London School explosion. The buildup of gas in the school went unnoticed, killing three hundred students and faculty when it ignited. Odorants are considered non-toxic in the extremely low concentrations occurring in natural gas delivered to the end user.

In mines, where methane seeping from rock formations has no odor, sensors are used, and mining apparatuses have been specifically developed to avoid ignition sources, e.g., the Davy lamp.

Explosions caused by natural gas leaks occur a few times each year. Individual homes, small businesses and boats are most frequently affected when an internal leak builds up gas inside the structure. Frequently, the blast will be enough to significantly damage a building but leave it standing. In these cases, the people inside tend to have minor to moderate injuries. Occasionally, the gas can collect in high enough quantities to cause a deadly explosion, disintegrating one or more buildings in the process. The gas usually dissipates readily outdoors, but can sometimes collect in dangerous quantities if weather conditions are right. However, considering the tens of millions of structures that use the fuel, the individual risk of using natural gas is very low.

Some gas fields yield sour gas containing hydrogen sulfide, which is toxic. Amine gas treating, an industrial process, is often used to remove hydrogen sulfide from natural gas.[13]

Extraction of natural gas (or oil) leads to decrease in pressure in the reservoir. This in turn may lead to subsidence at ground level. Subsidence may affect ecosystems, waterways, sewer and water supply systems, foundations, etc.

Natural gas heating systems are a minor source of carbon monoxide deaths in the United States. According to the US Consumer Product Safety Commission (2008), 56% of unintentional deaths from non-fire CO poisoning were associated with engine-driven tools like gas-powered generators and lawn mowers. Natural gas heating systems accounted for 4% of these deaths. Improvements in natural gas furnace designs have greatly reduced CO poisoning concerns. Detectors are also available that warn of carbon monoxide and/or explosive gas (methane, propane, etc.).

References

- ↑ Natural Gas Formation, Exploration, and Distribution From the website of the Pacific Gas and Electricity Company.

- ↑ Natural Gas From the website of the Climate Lab

- ↑ Mercury Removal from Natural Gas and Liquids UOP website page

- ↑ Air Dispersion Modeling Conversions and Formulas 1 normal cubic meter at 0 °C and 101.325 kPa absolute = 37.326 standard cubic feet at 60 °F and 14.695 psi absolute.

- ↑ Also referred to as the gross heating value (GHV)

- ↑ Also referred to as the net heating value (NHV)

- ↑ Proved reserves are those quantities of natural gas, which, by analysis of geological and engineering data, can be estimated with a high degree of confidence to be commercially recoverable from a given date forward, from known reservoirs and under current economic conditions.

- ↑ CIA World Factbook Country Comparison :: Natural gas - proved reserves

- ↑ Natural gas overview

- ↑ Pars Special Economic Energy Zone. Pars Special Economic Energy Zone. Retrieved on 2007-07-17.

- ↑ Natural Gas Processing: The Crucial Link Between Natural Gas Production and Its Transportation to Market

- ↑ Example Gas Plant

- ↑ 13.0 13.1 NaturalGas.org - Processing Natural Gas

- ↑ Natural Gas and the Environment

- ↑ NATURAL GAS VEHICLE STATISTICS. International Association for Natural Gas Vehicles]] (2008-12-31). Retrieved on 2009-06-11.

- ↑ Clean Engine Vehicle, Measurement and Control Laboratory

- ↑ PSC Tupolev - Development of Cryogenic Fuel Aircraft

- ↑ Gas Infrasturcture Europe, retrieved June 18. 2009

- ↑ Hyne, Norman J. (1991). Dictionary of petroleum exploration, drilling & production. pg. 190: PennWell Books, 625. ISBN 0878143521.

- ↑ Satellite observation of flares in the world

- ↑ satellite observation of methane in earth's atmosphere

- ↑ The Contours of the New Cold War

- ↑ Gazprom and Russian Foreign Policy

- External links

- CERA - collection of market and industry reports

- DOE/EIA EIA Natural Gas Weekly Update - current NG prices and market analysis

- Natural Gas Insight and Intelligence - Natural Gas Media - updated Natural Gas Industry News and Analysis for Traders, Investors, and Institutions