User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 18: | Line 18: | ||

* '''Wet steam''': A mixture of water plus steam (liquid plus vapor) at the [[boiling point|boiling point temperature]] of water at a given [[pressure]]. | * '''Wet steam''': A mixture of water plus steam (liquid plus vapor) at the [[boiling point|boiling point temperature]] of water at a given [[pressure]]. | ||

* '''Dry steam''': Steam, at the given pressure, that contains no water (also referred to as '''saturated steam'''). | * '''Dry steam''': Steam, at the given pressure, that contains no water (also referred to as '''saturated steam'''). | ||

* '''Superheatead''' steam: Dry steam, at the given pressure, that has been heated to a [[temperature]] higher than the boiling point of water at that pressure. | * '''Superheatead''' steam: Dry steam, at the given pressure, that has been heated to a [[temperature]] higher than the [[boiling point]] of water at that pressure. | ||

Referring to the adjacent drawing again, water is converted into wet, saturated or superheated steam in three steps: | Referring to the adjacent drawing again, water is converted into wet, saturated or superheated steam in three steps: | ||

Revision as of 16:00, 11 November 2009

Steam is the vapor (gaseous) phase of water (H2O). When the steam does not contain any liquid water, it is known as dry steam and it is completely colorless. However, when the steam contains tiny droplets of condensed liquid water, it appears to the eye as a white cloud (see the steam being vented from a geothermal power plant in the adjacent photograph).

What is very often referred to as smoke from cooling towers and other vents in industrial facilities is water vapor which has partially condensed and is mistaken to be white smoke.

Steam is manufactured in industrial processes by the boiling and vaporization of liquid water. It also occurs naturally by being vented from volcanoes, fumaroles, geysers and other geothermal sources.

Steam has a great many industrial and domestic uses. Probably the most important and by far the largest use of steam is in nuclear, fossil fuel and geothermal power plants .

Types of steam

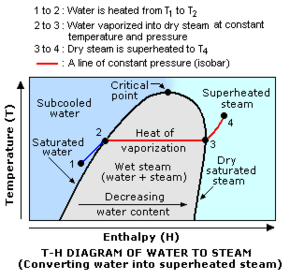

As shown in the adjacent diagram, there are three types of steam:

- Wet steam: A mixture of water plus steam (liquid plus vapor) at the boiling point temperature of water at a given pressure.

- Dry steam: Steam, at the given pressure, that contains no water (also referred to as saturated steam).

- Superheatead steam: Dry steam, at the given pressure, that has been heated to a temperature higher than the boiling point of water at that pressure.

Referring to the adjacent drawing again, water is converted into wet, saturated or superheated steam in three steps:

- Water at point 1 is heated to its boiling point at the given pressure of point 2 (the dark blue line). At that point the water is then referred to as saturated water.

- The water is then further heated at constant pressure (the red isobar from point 2 to point 3) to form wet steam. When it is completely vaporized (at point 3), it is then dry saturated steam.

- The dry saturated is then further heated at constant pressure (the red isobar from point 3 to point 4. The steam is then referred to as superheated steam.

Uses

Electricity generation

In the U.S., more than 86% of electric power is produced using steam as the working fluid, nearly all by steam turbines. Condensation of steam to water often occurs at the low-pressure end of a steam turbine, since this maximizes the energy efficiency, but such wet-steam conditions have to be limited to avoid excessive turbine blade erosion.

Cogeneration

In electric generation, steam is typically condensed at the end of its expansion cycle, and returned to the boiler for re-use. However in cogeneration, steam is piped into buildings through a district heating system to provide heat energy after its use in the electric generation cycle. The world's biggest steam generation system is the New York City steam system which pumps steam into 100,000 buildings in Manhattan from seven cogeneration plants.[1]

Steam engines

A steam engine uses the expansion of steam in order to drive a piston or turbine to perform mechanical work. The ability to return condensed steam as water-liquid to the boiler at high pressure with relatively little expenditure of pumping power is important. Engineers use an idealised thermodynamic cycle, the Rankine cycle, to model the behavior of steam engines.

Heat transfer in industrial process facilities

Other uses

- Sterilization

- An autoclave, which uses steam under pressure, is used in microbiology laboratories and similar environments for sterilization.

- Agricultural

- In agriculture steam is used for soil sterilization to avoid the use of harmful chemical agents and increase soil health.

- Domestic uses

- Steam's capacity to transfer heat is also used in the home: for cooking vegetables, steam cleaning of fabric and carpets, and heating buildings. In each case, water is heated in a boiler, and the steam carries the energy to a target object. "Steam showers" are actually low-temperature mist-generators, and do not actually use steam.

Steam tables and diagrams

Steam tables are tables of thermodynamic data for water/steam. They are often used by engineers and scientists in design and operation of equipment where thermodynamic cycles involving steam are used. Additionally, thermodynamic phase diagrams for water/steam, such as a temperature-entropy diagram or a Mollier diagram shown in this article, may be useful.

- ↑ Carl Bevelhymer, "Steam", Gotham Gazette, November 10, 2003