imported>Milton Beychok |

imported>Milton Beychok |

| Line 1: |

Line 1: |

| [[Image:Vacuum Column.jpg|right|thumb|183px|{{#ifexist:Template:Vacuum Column.jpg/credit|{{Vacuum Column.jpg/credit}}<br/>|}}Image 1: A vacuum distillation column in a petroleum refinery.]] | | [[Image:Vap-Liq Separator.png|thumb|right|246px|A typical vapor-liquid separator including commonly a de-entrainment pad and sometimes an inlet distributor]] |

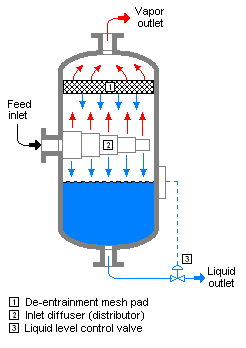

| | A '''vapor-liquid separator''' is a vertical vessel used in several industrial applications to separate a vapor-liquid mixture. Gravity causes the liquid to settle to the bottom of the vessel, where it is withdrawn.<ref>{{cite book|author=William D. Baasel|title=Preliminary Chemical engineering Plant Design|edition=2nd Edition|publisher=Van Nostrand Reinhold|year=1990|id=ISBN 0-442-23440-6}}</ref><ref>{{cite book|author=David H.F. Liu|title=Environmental Engineers' Handbook|edition=2nd Edition|publisher=[[CRC Press]]|year=1997|id=ISBN 0-8493-9971-8}}</ref><ref>{{cite journal|author=Stanley S. Grossel|year=2004 |month=June|title=Design and sizing of knock-out drums/catchtanks for emergency relief systems|journal=Plant/Operations Progress ([[AIChE]])|volume=5|issue=3|pages=129-135|issn=0278-4513}}</ref><ref>{{cite book|author=Stanley M. Walas|title=Chemical Process Equipment:Selection and Design|edition= |publisher=Butterworth- |

| | Heinemann|year=1988|id=ISBN 0-409-90131-8 }}</ref> The vapor travels upward at a design velocity which minimizes the [[Entrainment (engineering)|entrainment]] of any liquid droplets in the vapor as it exits the top of the vessel. |

|

| |

|

| [[Image:Vacuum Column.png|right|thumb|285px|{{#ifexist:Template:Vacuum Column.png/credit|{{Vacuum Column.png/credit}}<br/>|}}Image 2: Diagram of a vacuum column as used in [[Petroleum refining processes|petroleum refining]].]]

| | The feed to a vapor-liquid separator may also be a liquid that is being partially or totally [[Flash evaporation|''flashed'']] into a vapor and liquid as it enters the separator. |

|

| |

|

| '''Vacuum distillation''' is [[distillation]] of liquids performed at a [[pressure]] lower than [[atmospheric pressure]] to take advantage of the fact that reducing the pressure lowers the [[boiling point]] of liquids. This permits the distillation of liquids that are temperature sensitive and avoids any degradation of such liquids. | | A vapor-liquid separator may also be referred to as a '''flash drum''', '''knock-out drum''', '''knock-out pot''', '''compressor suction drum''' or '''compressor inlet drum'''. |

|

| |

|

| == Vacuum distillation in petroleum refining ==

| | When used to remove suspended water droplets from streams of air, a vapor-liquid separator is often called a '''[[Demister (Vapor)|demister]]'''. |

|

| |

|

| [[Petroleum crude oil]] is a complex mixture of hundreds of different [[hydrocarbon]] compounds generally having from 3 to 60 [[carbon]] [[atom]]s per [[molecule]], although there may be small amounts of hydrocarbons outside that range.<ref name=Handwerk>{{cite book|author=Gary, J.H. and Handwerk, G.E.|title=Petroleum Refining Technology and Economics|edition=2nd Edition|publisher=Marcel Dekker, Inc|year=1984|id=ISBN 0-8247-7150-8}}</ref><ref name=Leffler>{{cite book|author=Leffler, W.L. |title=Petroleum refining for the nontechnical person|edition=2nd Edition|publisher=PennWell Books|year=1985|id=ISBN 0-87814-280-0}}</ref><ref>{{cite book|author=James G, Speight|title=The Chemistry and Technology of Petroleum|edition=Fourth Edition|publisher=CRC Press|year=2006|id=0-8493-9067-2}}</ref> The refining of crude oil begins with distilling the incoming crude oil in a so-called [[Petroleum refining processes#The crude oil distillation unit|''atmospheric distillation column'']] operating at pressures slightly above atmospheric pressure.<ref name=Handwerk/><ref name=Leffler/><ref name=Kister>{{cite book|author=Kister, Henry Z.|title=Distillation Design|edition=1st Edition |publisher=McGraw-Hill|year=1992|id=ISBN 0-07-034909-6}}</ref>

| | ==Where vapor-liquid separators are used== |

|

| |

|

| In distilling the crude oil, it is important not to subject the crude oil to temperatures above 370 to 380 °C because the high [[molecular weight]] components in the crude oil will undergo [[thermal cracking]] and form [[petroleum coke]] at temperatures above that. Formation of coke would result in plugging the tubes in the [[furnace]] that heats the feed stream to the crude oil distillation column. Plugging would also occur in the [[piping]] from the furnace to the distillation column as well as in the column itself.

| | Vapor-liquid separators are very widely used in a great many indusries and applications, such as: |

|

| |

|

| The constraint imposed by limiting the column inlet crude oil to a temperature of more than 370 to 380 °C yields a residual oil from the bottom of the atmospheric distillation column consisting entirely of hydrocarbons that boil above 370 to 380 °C.

| | *[[Oil refinery|Oil refineries]] |

| | *[[Natural gas processing|Natural gas processing plants]] |

| | *[[Petrochemical]] and [[chemical plant]]s |

| | *[[Refrigeration|Refrigeration systems]] |

| | *[[Air conditioning]] |

| | *[[Gas compressor|Compressor systems for air or other gases]] |

| | *[[Pipeline transport|Gas pipelines]] |

| | *Steam condensate flash drums |

|

| |

|

| To further distill the residual oil from the atmospheric distillation column, the distillation must be performed at [[absolute pressure]]s as low as 10 to 40 [[mmHg]] (also referred to as [[Torr]]) so as to limit the operating temperature to less than 370 to 380 °C.

| | ==See also== |

|

| |

|

| Image 1 is a photograph of a large vacuum distillation column in a petroleum refinery and Image 2 is a process diagram of a petroleum refinery vacuum distillation column that depicts the internals of the column.

| | *[[Flash evaporation]] |

| | *[[Vapor-compression refrigeration]] |

| | *[[Souders-Brown equation]] (for sizing vapor-liquid separators) |

|

| |

|

| The 10 to 40 mmHg absolute pressure in a vacuum distillation column increases the volume of vapor formed per volume of liquid distilled. The result is that such columns have very large diameters.<ref>Karl Kolmetz, Andrew W. Sloley et al (2004), ''Designing Distillation Columns for Vacuum Service'', 11th India Oil and Gas Symposium and International Exhibition, September 2004, [[Mumbai]], [[India]] (also published in ''Hydrocarbon Processing'', May 2005)</ref>

| | ==References== |

|

| |

|

| Distillation columns such those in Images 1 and 2, may have diameters of 15 meters or more, heights ranging up to about 50 meters, and feed rates ranging up to about 25,400 cubic meters per day (160,000 barrels per day).

| | {{reflist}} |

|

| |

|

| The vacuum distillation column internals must provide good vapor-liquid contacting while, at the same time, maintaining a very low pressure increase from the top of the column top to the bottom. Therefore, the vacuum column uses [[distillation tray]]s only where withdrawing products from the side of the column (referred to as ''side draws''). Most of the column uses packing material for the vapor-liquid contacting because such packing has a lower pressure drop than distillation trays. This packing material can be either [[structured sheet metal]] or randomly dumped packing such as [[Raschig rings]].

| | ==External links== |

|

| |

|

| The absolute pressure of 10 to 40 mmHg in the vacuum column is most often achieved by using multiple stages of steam jet [[ejector]]s. <ref>[http://www.graham-mfg.com/ejphotos.html Photo gallery] (from website of Graham Manufacturing Company)</ref>

| | *[http://www.sulzerchemtech.com/Portaldata/11/Resources/Brochures/MTC/separator_e.pdf High-Capacity Gas De-Entrainment] (scroll to page 2 of the brochure) |

| | *[https://bora.uib.no/bitstream/1956/2007/1/Thesis_%20Austrheim.pdf ''Experimental Characterization of High-Pressure Natural Gas Scrubbers'' by Trond Austrheim] (PhD Thesis at the [[University of Bergen]], [[Norway]], 2006) |

| | *[http://www.spiraxsarco.com/resources/steam-engineering-tutorials/condensate-recovery/flash-steam.asp Flash Steam Tutorial] The benefits of recovering flash steam, how it is done and typical applications. |

| | *[http://www.red-bag.com/cms/index.php?section=242#criteria Design Criteria for Vapor/Liquid Separators] |

|

| |

|

| Many industries, other than the petroleum refining industry, use vacuum distillation on a much a smaller scale.

| |

|

| |

|

| ==Laboratory-scale vacuum distillation==

| | [[Category:Chemical engineering]] |

| | | [[Category:Oil refineries]] |

| [[Image:Vacuum distillation of DMSO at 70C.jpg|right|thumb|190px|{{#ifexist:Template:Vacuum distillation of DMSO at 70C.jpg/credit|{{Vacuum distillation of DMSO at 70C.jpg/credit}}<br/>|}}Image 3: [[Dimethyl sulfoxide]] boils at 189 °C at atmospheric pressure. Under vacuum, it distills at 70 °C.]] | | [[Category:Natural gas]] |

| | | [[Category:HVAC]] |

| Laboratory-scale vacuum distillation, sometimes referred to as ''low temperature distillation'', is used when the liquids to be distilled have high [[atmospheric boiling points]] or undergo a chemical change at temperatures near their atmospheric boiling points.<ref>[http://www.epa.gov/esd/chemistry/vacuum/default.htm Vacuum Distillation: New Method for Analyzing Organic Chemicals in a Wide Array of Samples] ([[United States Environmental Protection Agency]])</ref><ref>[http://www.newton.dep.anl.gov/askasci/chem00/chem00635.htm What is vacuum distillation?] ([[Argonne National Laboratory]]'s NEWTON Ask-A-Scientist)</ref>

| | [[Category:Industrial processes]] |

| | | [[Category:Separation processes]] |

| Temperature sensitive materials (such as [[beta carotene]]) also require vacuum distillation to remove [[solvent]]s from the mixture without damaging the product.

| | [[Category:Compressors]] |

| | | [[Category:Unit operations]] |

| There many laboratory applications for vacuum distillation as well as many types of distillation setups and apparatuses. Image 3 is a photograph of a vacuum distillation setup in a laboratiry.

| |

| | |

| Safety is an important consideration when using glassware as part of the setups. All of the glass components should be carefully examined for scratches and cracks which could result in implosions when the vacuum is applied. Wrapping as much of the glassware with tape as is practical helps to prevent dangerous scattering of glass shards in the event of an implosion.

| |

| | |

| [[Image:Rotary Evaporation.png|right|thumb|350px|{{#ifexist:Template:Rotary Evaporation.png/credit|{{Rotary Evaporation.png/credit}}<br/>|}}Image 4: Rotary evaporation laboratory setup.]] | |

|

| |

| ===Rotary evaporation===

| |

| | |

| [[Rotary evaporation]]<ref>[http://www.chem.ubc.ca/courseware/235/danalabsess/rotovap.html Operation of a Rotary Evaporator (Rotovap)] (from the website of the [[University of British Columbia]])</ref> is a type of vacuum distillation apparatus used to remove bulk [[solvent]]s from the liquid being distilled. It is also used by environmental regulatory agencies for determining the amount of solvents in paint, coatings and inks.<ref>http://aqmd.gov/tao/methods/lab/303-91.pdf [[SCAQMD]] Test method 302-91]</ref> Image 4 is a diagram of one such setup. | |

| | |

| Rotary evaporation setups include an apparatus referred to as a ''Rotovap'' which rotates the distillation flask (sometimes called the ''still pot'') to enhance the distillation. Rotating the flask throws up liquid on the walls of the flask and thus increases the surface area for evaporation.

| |

| | |

| Heat is often applied to the rotating distillation flask by partially immersing it in a heated bath of water or oil. Typically, the vacuum in such systems is generated by a water [[aspirator]] or a [[vacuum pump]] of some type.

| |

| | |

| ===Perkin triangle apparatus===

| |

| | |

| Some compounds have high boiling points as well as being [[air sensitive]]. A simple laboratory vacuum distillation glassware setup can be used, whereby the vacuum is replaced with an inert gas after the distillation is complete. However, this is a less satisfactory system if one desires to collect fractions under a reduced pressure. For better results or for very air sensitive compounds, a [[Perkin triangle]] apparatus can be used.

| |

| | |

| The Perkin triangle uses a series of glass or [[Teflon]] valves to allow fractions to be isolated from the distillation flask without the main body of the distillation setup being removed from either the vacuum or the heat source, and thus can remain in a state of [[reflux]]. To do this, the sample collection vessel is first isolated from the vacuum by means of the valves, the vacuum over the sample is then replaced with an inert gas (such as [[nitrogen]] or [[argon]]) and can then be stoppered and removed. A fresh collection vessel can then be added to the system, evacuated and linked back into the distillation system via the valves to collect a second fraction, and so on, until all fractions have been collected.

| |

| | |

| ==References==

| |

| {{reflist}}

| |