Integral Fast Reactor: Difference between revisions

m (→Safety) |

|||

| Line 20: | Line 20: | ||

1) The metal fuel, a low melting point alloy of U-Pu-Zr, will melt if the rod ever gets too hot. The fuel then expands upward in the steel cladding, shutting down the fission reactions (see Figure 1). The IFR is "walk away safe".<br> | 1) The metal fuel, a low melting point alloy of U-Pu-Zr, will melt if the rod ever gets too hot. The fuel then expands upward in the steel cladding, shutting down the fission reactions (see Figure 1). The IFR is "walk away safe".<br> | ||

2) Many of the fission products bind chemically with sodium, reducing the risk of fission product release if there is fuel failure.<br> | 2) Many of the fission products bind chemically with sodium, reducing the risk of fission product release if there is fuel failure.<br> | ||

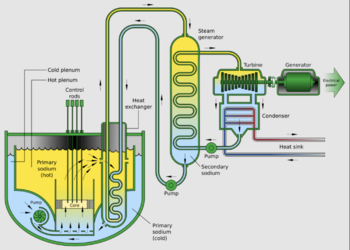

3) Convection in the large pool of molten sodium will easily handle the decay heat after a shut-down (see Figure 2).<br> | 3) Convection and a large thermal inertia in the large pool of molten sodium will easily handle the decay heat after a shut-down (see Figure 2).<br>fuel | ||

4) The reactor vessel has no penetrations below the top of the pool, eliminating the possibility of sodium leakage.<br> | 4) The reactor vessel has no penetrations below the top of the pool, eliminating the possibility of sodium leakage.<br> | ||

5) There is no high pressure or any water near the reactor vessel.<br> | 5) There is no high pressure or any water near the reactor vessel.<br> | ||

6) The entire reactor | 6) The entire reactor vessel is not filled solid, to allow for thermal expansion and contraction during operation. The space above the sodium pool is filled with argon gas so that air never contacts the sodium.<br> | ||

Full-scale reactor tests were conducted at Argonne National Laboratory (West) in Idaho (now Idaho National Laboratory), in which the primary coolant pump was stopped with the reactor running at full power. All safety systems were disabled, and the control rods were held fully withdrawn. These "unprotected loss-of-flow tests" simulate the | Full-scale reactor tests were conducted at Argonne National Laboratory (West) in Idaho (now Idaho National Laboratory), in which the primary coolant pump was stopped with the reactor running at full power. All safety systems were disabled, and the control rods were held fully withdrawn. These "unprotected loss-of-flow tests" simulate the | ||

extreme scenario where all safety systems and operator actions have failed. | extreme scenario where all safety systems and operator actions have failed. | ||

The | The chain reaction was terminated by core expansion, and the core was cooled by natural circulation, without fuel damage or radioactive leakage.<ref name=IFRtests/> | ||

== Waste Management == | == Waste Management == | ||

Revision as of 15:20, 25 April 2023

The Integral Fast Reactor (IFR) is Argonne Lab's best design,[1] a metal-fueled, sodium-cooled, pool-type [2] Fast Neutron Reactor, addressing all the issues raised in Nuclear_power_reconsidered (safety, waste management, weapons proliferation, and cost). "Integral" refers to the on-site reprocessing of the spent fuel.

Choice of Fuel and Coolant

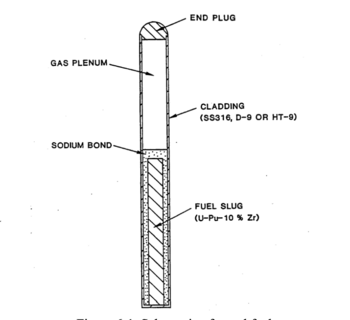

The IFR has a unique design for its fuel rods that accommodates much higher burnup than in light water reactors (LWRs) and also provides inherent safety if temperatures increase.

In standard light water reactor (LWR) fuel rods, the fuel-clad gap is filled with helium gas for thermal bonding. If burnup is too high, the swelling and/or the oxide fuel cracking from thermal stresses will mechanically contact and strain the cladding to failure. These problems have been addressed in LWR fuel designs, but maximum burnup is limited by these effects. In IFR fuel, which is metallic, high burnup is achieved because the large initial fuel-cladding gap is filled with highly conductive liquid metal sodium that provides excellent thermal contact but still accommodates swelling at high burnup. Gaseous fission products that escape the fuel meat accumulate in the plenum above the fuel without unduly increasing the fuel rod internal pressure. See Figure 1.

In oxide-fueled LWRs clad with zirconium alloy, two chemical effects are disadvantagous. First, as happened at Fukushima, if the cladding temperature becomes too high in the presence of water, the zirconium alloy clad rapidly oxidizes, weakening the cladding and producing elemental hydrogen. Second, in the event of a cladding breach, the oxide fuel meat reacts with water.

In the IFR, parasitic fast neutron capture in cladding is far lower than parasitic thermal neutron capture in LWR cladding. (Zircaloy is used in LWRs because of its low neutron absorption.) This permits use of steel cladding without adversely impacting the neutron economy, and steel does not suffer the rapid oxidation at high temperature that zirconium alloys do. If there is a cladding breach, fission products entering the coolant are bound there rather than released.

The thermal expansion coefficient of metallic fuel provides a negative reactivity feedback. If the fuel temperature increases, the fuel and coolant both expand, increasing neutron leakage from the core and thereby reducing the neutron chain reaction naturally.

Safety

The safety of the IFR design is ensured by several features:

1) The metal fuel, a low melting point alloy of U-Pu-Zr, will melt if the rod ever gets too hot. The fuel then expands upward in the steel cladding, shutting down the fission reactions (see Figure 1). The IFR is "walk away safe".

2) Many of the fission products bind chemically with sodium, reducing the risk of fission product release if there is fuel failure.

3) Convection and a large thermal inertia in the large pool of molten sodium will easily handle the decay heat after a shut-down (see Figure 2).

fuel

4) The reactor vessel has no penetrations below the top of the pool, eliminating the possibility of sodium leakage.

5) There is no high pressure or any water near the reactor vessel.

6) The entire reactor vessel is not filled solid, to allow for thermal expansion and contraction during operation. The space above the sodium pool is filled with argon gas so that air never contacts the sodium.

Full-scale reactor tests were conducted at Argonne National Laboratory (West) in Idaho (now Idaho National Laboratory), in which the primary coolant pump was stopped with the reactor running at full power. All safety systems were disabled, and the control rods were held fully withdrawn. These "unprotected loss-of-flow tests" simulate the

extreme scenario where all safety systems and operator actions have failed.

The chain reaction was terminated by core expansion, and the core was cooled by natural circulation, without fuel damage or radioactive leakage.[4]

Waste Management

Fuel rods have an advantage over molten salt fuels in that the fission products are contained in the rod. This means a smaller volume of radioactive spent fuel. Also rods are easy to identify and count, which may be advantageous in preventing diversion. A typical 500 MWe MSR produces 13 tonnes of Spent Nuclear Fuel (SNF) per year. A 500 MWe PWR produces about 11 tonnes per year. A 500 MWe IFR produces about 5 per year of (High Level Waste) HLW. Note: SNF can be reprocessed, and the final amount of HLW will depend on the details of that process.

Weapons Proliferation

The chemistry of the IFR fuel process does not allow extraction of weapons-grade material at any point in the cycle. Spent fuel is a mix of uranium, plutonium, and various actinides. Processing would be necessary by some other unrelated process, a situation not different in kind from starting with unprocessed fuel. So the IFR adds little or nothing to proliferation risk.[5] In countries not licensed for fuel processing, return of the spent fuel to a secure location could be handled as any other reactor with solid fuel rods. Rods are easy to count, and the number in transit at any one time can be small enough to avoid theft of a large quantity.

Cost

- No enormous pressure vessel with 6-inch steel walls.

- No huge containment building with 6-foot think, steel reinforced concrete walls.

Notes and References

- ↑ PLENTIFUL ENERGY The Story of the Integral Fast Reactor, Charles Till and Yoon Il Chang, 2011.

- ↑ The alternative "loop-type" is necessary in standard Pressurized Water Reactors. A low pressure coolant allows a larger "pool-type" reactor vessel capable of absorbing all the heat in an emergency shutdown. See Till & Chang, Section 5.4 The Reactor Configuration Choice.

- ↑ Schematic of the metal fuel rod. Fig.6.1 in Till & Chang, Chapter 6 IFR Fuel Characteristics.

- ↑ Experimental Confirmations of Limited Damage in the Most Severe Accidents,Till & Chang, Section 7.10.

- ↑ Nonproliferation Aspects of the IFR, Till & Chang, Chapter 12.