User:Milton Beychok/Sandbox

Large-scale trickle filters for wastewater treatment

A trickle filter consists of a fixed bed of rocks, gravel, slag, polyurethane foam or plastic media over which sewage or other wastewater percolates downward and is contacted with a layer or film of microbial slime covering the bed media. Aerobic conditions are maintained by air flowing through the bed.[1][2][3][4]

The terms trickling biofilter, biofilter, biofilm reactor, biological filter, biological trickling filter and biotower are often used to refer to a trickle filter. These systems have also been described as an attached growth process , a fixed film process, packed media bed filters and percolating filters.

Process mechanism

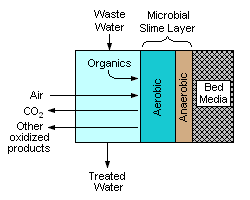

Referring to Figure 2, the process mechanism involves adsorption of any organic compounds in the sewage or other wastewater by the layer of microbial slime followed by the diffusion of air into the slime layer to furnish the oxygen (O2) required for the biochemical oxidation of the organic compounds that results in releasing gaseous carbon dioxide (CO2), water (H2O) and other oxidized by-products.[1][3][4] The air may be provided by natural draft or by forced aeration using large fans or blowers.

The aerobic biochemical oxidation occurring in a trickle filter may be expressed as:

- Organic compounds + microbes + nutrient + O2 → oxidized organics + CO2 gas + H2O

As the slime layer thickens, it becomes more difficult for air to penetrate the layer and an inner anaerobic layer is formed. For some plastic media , this inner layer will build up and eventually slough off the smooth plastic into the treated effluent water as a sludge that requires subsequent removal and disposal. The sludge consists of dead microbes, non-gaseous oxidized materials, inorganic minerals which are not biodegradable and other substances.

Other than the primary carbon dioxide, water and sludge by-products of the biochemical processes occurring in a trickle filter, there may also be some by-product nitrogen (N2) and methane (CH4) gases.

The following conditions result in the sloughing off of part of the microbial slime layer (referred to as the biofilm) and are intentionally or unintentionally used for control of the biofilm:[1]

- Hydraulic erosion by the continous flow of water across the surface of the biofilm

- Degradation of the microbes at the interface of the biofilm and surface of the plastic media resulting in a loss of adhesion

- Formation of gases in the biofilm such as carbon dioxide, nitrogen and methane

An ideal filter media is a media that optimizes the surface area for microbial attachment and wastewater retention time, has a high permeability that maximizes air flow, resists plugging and does not degrade.

Configuration of large-scale trickle filters

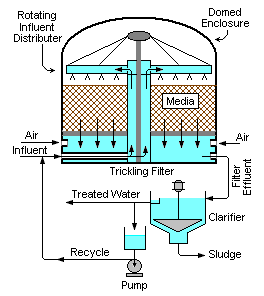

Figure 3 schematically depicts a typical large-scale trickle filter such as in the photograph shown in Figure 1. Most large-scale trickle filter systems share the same fundamental components:

- A large containment tank or structure which houses the bed of filter medium

- A filter medium upon which beneficial a beneficial microbial film is promoted and developed

- A distribution method for applying the influent wastewater to the filter medium

- A system, such as a clarifier, for removing the sludge from the treated effluent.

- A pumping system for recycling a portion of the clarified, treated effluent

Each of the two arms of the rotating influent water distributor has nozzles that discharge the water in opposite directions, so that the reaction forces of the discharged jets of water cause the distributor to rotate.

Systems can be configured for single-pass use where the influent wastewater is treated in a trickle filter once before being disposed of, or for multi-pass use where a portion of the treated effluent is recycled back to the trickle filter and re-treated. Multi-pass systems result in better effluent quality and assist in reducing the amount of nitrogen-containing compounds by promoting denitrification in the overall system.

Where large-scale trickle filters are used

Most large-scale trickle filters are used in:

- In municipal wastewater treatment facilities, also referred to as

Publically Owned Treatment Works (PTOW's).

- Onsite within industrial facilities that produce large amounts of wastewaters, such as petroleum refineries and petrochemical or chemical plants.

There are a number of different designs for industrial wastewater trickling filters. Three of the more commonly used designs are large tanks or concrete enclosures, vertical towers or rotating biological filters.

Tanks or concrete enclosures

- Large tanks or concrete enclosures filled with plastic packing or other media as shown in Image 2

Vertical towers

The availability of inexpensive plastic tower packings has led to their use as trickling filter beds in tall towers, some as high as 20 meters.[4] As early as the 1960s, such towers were in use at: the Great Northern Oil's Pine Bend Refinery in Minnesota; the Cities Service Oil Company Trafalgar Refinery in Oakville, Ontario and at a kraft paper mill.[7]

Miscellaneous design features

The treated water effluent from industrial wastewater trickling filters is very often subsequently processed in a clarifier-settler to remove the sludge that sloughs off of the microbial slime layer attached to the trickling filter media (see Image 1 above).

Currently, some of the latest trickle filter technology involves aerated biofilters which are essentially trickle filters consisting of plastic media in vessels using blowers to inject air at the bottom of the vessels, with either downflow or upflow of the wastewater.[8]

Regulatory requirements

Many countries regulate the composition of treated water effluents from industrial facilities. For example, in the United States, the Clean Water Act mandates a National Pollutant Discharge Elimination System (NPDES), which regulates industrial point sources that discharge pollutants into rivers, lakes, and oceans. All U.S. industrial facilities that discharge liquid effluents must obtain effluent discharge permits under that system.

References

- ↑ 1.0 1.1 1.2 Duncan Mara abd Nigel J. Horan (Editors) (2003). Handbook of Water and Wastewater Microbiology, 1st Edition. Academic Press. ISBN 0-12-470100-0.

- ↑ Marcos Von Sperling (2007). Activated Sludge and Aerobic Biofilm Reactors, 1st Edition. IWA Publishing. ISBN 1-84339-165-1.

- ↑ 3.0 3.1 Paul L. Bishop (2004). Pollution Prevention: Fundamentals and Practice. Waveland Press. ISBN 1-57766-348-9. Lecture on Chaper 11: Residuals Management

- ↑ 4.0 4.1 4.2 Milton R. Beychok (1967). Aqueous Wastes from Petroleum and Petrochemical Plants, 1st Edition. John Wiley and Sons. LCCN 67019834. Cite error: Invalid

<ref>tag; name "Beychok" defined multiple times with different content - ↑ Biological filter and process U.S. patent 4,351,729, September 28, 1982, Assigned to Celanese Corporation

- ↑ Lecture by Dr. Allen Davis, Auburn University, page 6 of 8 pdf pages including schematic of packed tower trickling filter)

- ↑ E.H. Bryan and D.H. Moeller, Aerobic Biological Oxidation Using Dowpac, Paper 42, Conference on Biological Waste Treatment, Manhattan College, April 20, 1960. [1]

- ↑ Marcus Van Sperling (2007). Activated Sludge and Aerobic Biofilm Reactors. IWA Publications. ISBN 1-84339-165-1.

The treatment of sewage with trickling filters is among the oldest and most well characterized treatment technologies.

Onsite sewage facilities (OSSF) are recognized as viable, low-cost, long-term, decentralized approaches to sewage treatment if they are planned, designed, installed, operated and maintained properly (USEPA, 1997).

Sewage trickling filters are used in areas not serviced by municipal wastewater treatment plants (WWTP). They are typically installed in areas where the traditional septic tank system are failing, cannot be installed due to site limitations, or where improved levels of treatment are required for environmental benefits such as preventing contamination of ground water or surface water.

Sites with a high water table, high bedrock, heavy clay, small land area, or which require minimal site destruction (for example, tree removal) is desired are ideally suited to trickling filters.

All varieties of sewage trickling filters have a low and sometimes intermittent power consumption. They can be somewhat more expensive than traditional septic tank-leach field systems, however their use allows for better treatment, a reduction in size of disposal area, less excavation, and higher density land development.