User:Milton Beychok/Sandbox

Jump to navigation

Jump to search

The fluid catalytic cracker (FCC) is the most important conversion process unit used in petroleum refineries. It is widely used to convert the high-boiling hydrocarbon fuel oils in petroleum crude oils to more valuable gasoline and other products.[1][2][3] The feedstock to an FCC is usually that portion of the crude oil that has an initial boiling point of 330 °C or higher at atmospheric pressure.

As of 2006, FCC units were in operation at 400 petroleum refineries worldwide and about one-third of the crude oil refined in those refineries is processed in an FCC to produce high-octane gasoline, diesel oil and fuel oil.[2][4]

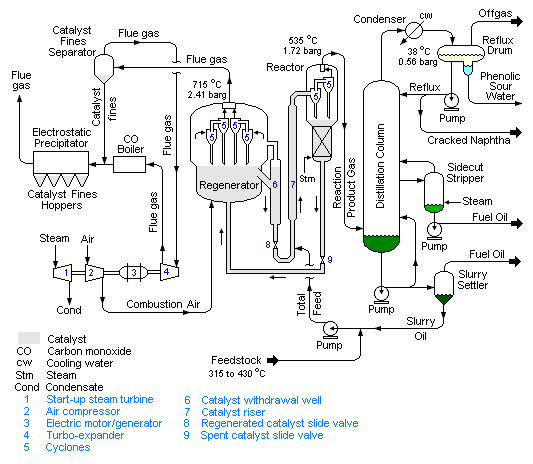

Flow diagram and process description

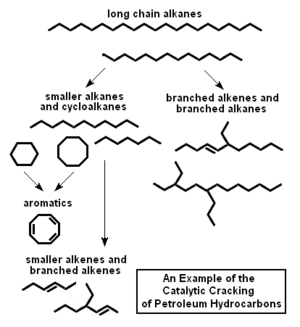

Chemistry

Catalysts

History

References

- ↑ James H. Gary and Glenn E. Handwerk (2001). Petroleum Refining: Technology and Economics, 4th Edition. CRC Press. ISBN 0-8247-0482-7.

- ↑ 2.0 2.1 James. G. Speight (2006). The Chemistry and Technology of Petroleum, 4th Edition. CRC Press. ISBN 0-8493-9067-2.

- ↑ Reza Sadeghbeigi (2000). Fluid Catalytic Cracking Handbook, 2nd Edition. Gulf Publishing. 0-88415-289-8.

- ↑ David S.J. Jones and Peter P.Pujado (Editors) (2006). Handbook of Petroleum Processing, First Edition. Springer. ISBN 1-4020-2819-9.