User:Milton Beychok/Sandbox

Condensate polishing is a process used to purify the steam condensate produced in high-pressure steam generation facilities[1][2][3][4] such as those in large thermal power plants.[5] Steam condensate is the water formed by condensing the exhaust steam from the steam-driven turbines in thermal power plants and which is recycled for reuse as the major part of the steam generation feedwater.

Condensate polishing is a unique application of ion-exchange resins that removes suspended and dissolved impurities from the condensate. It is essential for the very stringent quality required of high-pressure steam generation feedwater.

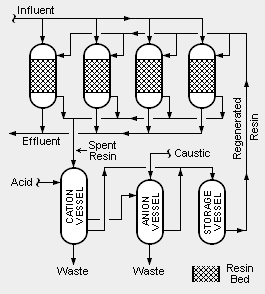

Types of condensate polishing

How condensate polishing works

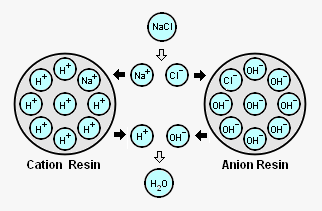

Ion exchange is a reversible chemical reaction wherein ions (atoms or molecules that have lost or gained an electron and thus acquired an electrical charge) present in a solution are exchanged for a similarly charged ion attached to an immobile solid particle of ion exchange material.

By charging (i.e., treating) ion exchange material with an acid, usually sulfuric acid (H2SO4) or hydrochloric acid (HCl), positively charged hydrogen ions (H+) are attached to sites on the ion exchange material. Those sites will attract other positively charged ions (called cations) present in a solution brought into contact with the positively charged H+ ions.

Similarly, by charging ion exchange material with a caustic such as sodium hydroxide (NaOH), negatively charged hydroxide ions (OH-) are attached to sites on the ion exchange material. Those sites will attract other negatively charged ions (called anions) present in a solution brought into contact with the negatively charged OH- ions.

The adjacent diagram schematically depicts an acid treated bead of ion exchange resin with its attached H+ ions (referred to as cation resin) and a caustic treated bead of ion exchange resin with its attached OH- ions (referred to as an "anion resin").

The water first passes through the cation bed. The resins beads have been charged with acid, usually sulfuric or hydrochloric. The resin has a greater attraction for the incoming cations, usually calcium, magnesium, sodium and iron and so retains them, releasing the H+ ions. So the effluent of the cation bed is acidic.

The cation effluent then goes to the anion bed, that has been charged with OH -ions from sodium hydroxide. The anions, Cl-, SO4--, CO3--, etc. are exchanged for the OH- by the resins.

Amazingly enough, the H+ ions from the cation resins and the OH- ions released by the anion resins neutralize each other and form water, so if everything is working correctly, the effluent of the anion bed is at a neutral pH.

References

- ↑ Larry Drbal, Kayla Westra and Pat Boston (1996). Power Plant Engineering, 1st Edition. Springer. ISBN 0-412-06401-4.

- ↑ Brad Buecker (2000). Fundamentals of Steam Generation Chemistry, 1st Edition. Penwell. ISBN 0-87814-750-0.

- ↑ Condensate Polishing Guidelines Electric Power Research Institute (EPRI), 1996

- ↑ Condensate Polishing State of Knowledge Assessment Electric Power Research Institute (EPRI), 2006

- ↑ Either nuclear or fuel-fired power plants