User:Milton Beychok/Sandbox

A steam generator is a device that uses a heat source to boil liquid water and convert it into its vapor phase, referred to as steam. The heat may be derived from the combustion of a fuel such as coal, petroleum fuel oil, natural gas, municipal waste or biomass, a nuclear fission reactor and other sources.

There are a great many different types of steam generators ranging in size from small medical and domestic humidifiers to large steam generators used in conventional coal-fired power plants that generate about 3,500 kilograms of steam per megawatt-hour of energy production. The adjacent photo depicts an 1150 MW power plant with three steam generators which generate a total of about 4,025,000 kg/hour of steam.

Many small commercial and industrial steam generators are referred to as "boilers". In common usage, domestic water heaters are also referred to as "boilers". However, domestic water heaters do not boil water nor do they generate any steam.

Evolution of steam generator designs

- Fire-tube boilers[1]

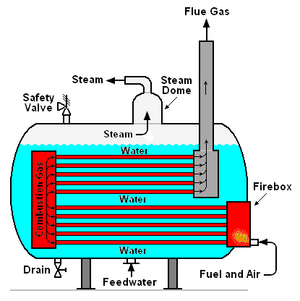

In the late 18th century, various design configurations of fire-tube boilers began to be widely used for steam generation in industrial plants, railway locomotives and steamboats. Fire-tube boilers are so named because the fuel combustion product gases flow through tubes surrounded by water contained in an outer cylindrical drum (see Figure 1). Today, steam-driven locomotives and river boats have virtually disappeared and fire-tube boilers are not used for steam generation in modern utility power plants.

However, they are still used in some industrial plants to generate saturated steam at pressures of up to about 18 bar and at rates ranging up to about 25,000 kg/hour. In that range, fire-tube boilers offer low capital cost, operational reliability, rapid response to load changes and no need for highly skilled labor.

The major shortcoming of fire-tube boilers is that the water and steam are contained within the outer cylindrical shell and that shell is subject to size and pressure limitations. The tensile stress (or hoop stress) on the cylindrical shell walls is a function of the shell diameter and the internal steam pressure:[2]

| where: | = tensile stress (or hoop stress), Pa |

| = Internal gauge pressure, Pa | |

| = internal diameter of cylindrical shell, m | |

| = thickness of cylindrical shell wall, m |

The ever-growing need for increased quantities of steam at higher and higher pressures could not be provided by fire-tube boilers because, as can be seen in the above equation, both higher pressures and larger diameter shells led to prohibitively thicker and more expensive shells.

- Water-tube boilers

Water-tube boilers with logitudinal steam drums, as in Figure 2,[3] were developed to allow increases in generated steam pressure and increased capacity. The water-tube boilers, in which water flowed through inclined tubes and the combustion product gases flowed outside the tubes, put the desired higher steam pressures in the small diameter tubes which could withstand the tensile stress of higher pressures without requiring excessively thick tubewalls.[1]

The relatively smaller steam drums (in comparison with the fire-tube shells) were also capable of withstanding the tensile stress of the desired higher pressures without needing excessively thick drum walls.

The water-tube boiler went through several stages of design and development. The steam drum was arranged either parallel to the tubes (as shown in Figure 2) or transverse to the tubes, in which case the boiler was referred to as being a "cross drum" rather than a "longitudinal drum" boiler. Cross drum boilers could accomodate more tubes than longitudinal drum boilers and they were designed to generate steam pressures of up to about 100 bar and at rates ranging up to about 225,000 kg/hour.

The next stage of development involved using three to four steam drums, bent tubes and one to two mud drums at the bottom of the tubes. Such designs were referred to as Stirling boilers,[4] named after Alan Stirling who designed his first boiler in 1883 and formed the Stirling Boiler Company of New York a few year later. The bent tubes entered and exited the steam drums radially which provided better steam-water separation in the steam drums. The tubes in a Stirling boiler were easily accessed, which made for easier inspection and maintenance or replacement of the tubes. The Stirling boilers with four steam drums were superseded by a simpler two drum design with a steam drum directly above a water (mud) drum and bent water tubes connecting the two drums.[1]

The Babcock and Wilcox Company purchased and assimilated the Stirling Boiler Company in 1906.[5] Although widely used for large steam generating plants in the period between 1900 and World War II (the early 1940's), Stirling boilers are rarely seen today.

Modern steam generators

Modern steam generators can be classified from the viewpoint of applications as :

- Utility steam generators

- Industrial steam generators

- Marine steam generators

References

- ↑ 1.0 1.1 1.2 P.K. Nag (2008). Power Plant Engineering, 3rd Edition. Tata McGraw-Hill. ISBN 0-07-064815-8.

- ↑ Pressure vessels:Combined stress From the website of the Mechanical Engineering Department at the University of Washington

- ↑ Babcock and Wilcox Company (1922). Steam, Its Generation and Use, 35th Edition, 6th issue. Bartlett Orr Press, New York. Google Books

- ↑ The Engineering Staff of the Stirling Company (1905). A Book on Steam for Engineers, 1st Edition. The Stirling Company. Google Books

- ↑ Stirling Boilers From the websote of the American Society of Mechanical Engineers (ASME).