User:Milton Beychok/Sandbox

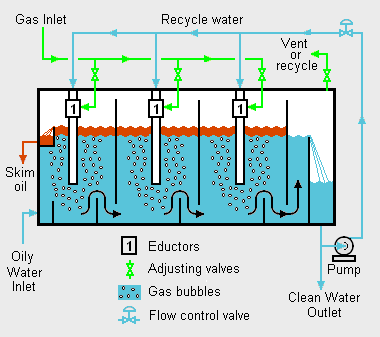

Induced gas flotation (IGF) is a treatment process that clarifies wastewaters (or other waters) by the removal of suspended oil. The removal is achieved by introducing very small bubbles of air or other gases into the water or wastewater. The bubbles adhere to and enhance the buoyancy of the suspended oil which accelerates the rate at which the oil floats to the surface of the water where it can then be skimmed off for removal (see the adjacent drawing).

Induced gas flotation is widely used by the oil and gas industry in onshore and offshore oil and gas production facilities as part of the equipment used to de-oil their wastewaters (called "production water").

A similar process, known as dissolved air flotation (DAF) is commonly used in treating the wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants.

Types of flotation processes

There are various types of flotation processes that use dispersed gas bubbles as the flotation agent. The primary difference between the various types is the manner in which the gas bubbles are formed.

Dissolved air flotation (DAF)

In the this process, a portion of the clarified wastewater leaving the flotation vessel is pumped into a separate, small pressure vessel (called the air drum) into which compressed air is also introduced. This results in saturating the pressurized effluent water with the air. The air-saturated water stream is recycled to the front of the float tank and flows through a pressure reduction control valve just as it enters the front of the flotation vessel, which results in the air being released in the form of small bubbles.

In some installations, an inert gas (such as nitrogen) is used rather than air in order to avoid possibly creating a flammable or explosive condition. In such cases the process is referred to as Dissolved gas flotation (DGF).

Induced gas flotation (IGF)

In this process the the gas is drawn into the flotation vessel to form bubbles internally within the flotation vessel. There are two-subtypes of the IGF process:

- Mechanical-type IGF: In this IGF subtype, gas is drawn into the flotation vessel by a rotating impeller within the flotation vessel (driven by an electric motor mounted on the vessel exterior) and mixed with the wastewater to form bubbles within the flotation vessel.

- Hydraulic-type IGF: As shown in Fig.1, in this IGF subtype, a portion of the clarified wastewater leaving the flotation vessel is recycled back into the flotation vessel by a pump. The recycled water enters the vessel through an internal pipe that contains an eductor which draws air into the pipe and mixes it with the wastewater water to form bubbles within the flotation vessel.

As mentioned above, the

Process mechanism

The feed water is to the IGF float tank is often (but not always) dosed with a coagulant (such as ferric chloride or aluminum sulfate) to flocculate the suspended

IGF and DGF involve the introduction of fine gas bubbles that attach to the oil and fine solids in the produced water and then float to the surface where they are removed to slop oil systems. Flotation units can remove up to 95% of free oil and are most commonly used as a process step downstream of gravity separation to meet discharge limits or to reduce the load on filtration systems. Inlet oil content should not exceed 1000 ppmv and should preferably be below 300 ppmv.

Produced gas recirculation is generally used to generate the micro bubbles. The introduction of air is not recommended in produced water systems because this makes the water very corrosive to steels, leads to the precipitation of dissolved solids and can result in the creation of flammable gas mixtures.

Produced gas recirculation is generally used to generate the micro bubbles. The introduction of air is not recommended in produced water systems because this makes the water very corrosive to steels, leads to the precipitation of dissolved solids and can result in the creation of flammable gas mixtures.

Several types of gasses can be used for gas flotation, including air, natural gas, nitrogen or carbon dioxide. The free oil in water content of the effluent will vary depending on the operating conditions. Generally, it may be expected to run between 1 and 10%25 of the inlet oil concentration under normal operating conditions. Most IGF units work best with inlet oil concentrations ranging between 50 and 500 parts per million.

Aker Solutions IGF units are custom designed horizontal units with six cells or compartments; an inlet cell, four flotation cells, an outlet cell, and a skimmed oil cell. Our IGF units are hydraulic type units, where the gas bubbles are hydraulically introduced into the water stream via a recycle pump and eductors or by dissolving the gas into the water stream using a specially designed pump.

IGF Units in the oil industry do not use air as the flotation medium due to the explosion risk. These IGF Units use natural gas to create the bubbles.

The Educator creates a gas-rich fluid stream of small bubbles

References

- Chapter VIII, Produced Water Characterization, Control and Treatment Technologies Part of the U.S. EPA publication EPA-821-R-96-023, Development Document for Final Effluent Limitations Guidelines and Standards for the Coastal Subcategory of the Oil and Gas Extraction Point Source Category, October 1995